Our coated microplates are critical for developing highly sensitive and specific IVD assays, enabling accurate detection and quantification of disease biomarkers. This includes applications in infectious disease testing, cancer diagnostics, and autoimmune disease monitoring, where precise capture of antigens or antibodies is essential for reliable patient results.

Creative Biolabs stands as a recognized leader in in vitro diagnostics (IVD), offering comprehensive IVD antibody development platforms and bespoke services. We are proud to introduce our advanced microplate coating solutions, designed to optimize disease diagnosis and biochemical reaction monitoring, alongside fully customized coating processes tailored precisely to your unique project requirements.

Microplates Coating

Microplate coating involves the precise modification of the inert polystyrene surfaces within microplate wells to enable the stable and efficient immobilization of critical biological molecules. This foundational process is essential for a myriad of assays, including immunoassays and nucleic acid hybridization. While traditional methods often rely on passive adsorption, leading to limitations such as low binding capacity and non-specific interactions, advanced coating techniques employed significantly enhance surface functionality. These innovations ensure superior ligand immobilization, ultimately boosting assay sensitivity, specificity, and overall reproducibility.

Fig.1 Coated Microplate.

Fig.1 Coated Microplate.

Advantages of Our Microplates Coating Platform

- Enhanced Binding Capacity: Our coatings significantly increase the available surface area for ligand immobilization, allowing for a greater and more uniform capture of target molecules, which directly translates to stronger signals.

- Reduced Non-Specific Binding: Through precise surface chemistry, our coated plates actively minimize undesirable interactions, leading to lower background noise and cleaner, more specific assay results.

- Unparalleled Reproducibility: Our meticulously controlled coating processes guarantee consistent surface properties across every well and every batch, providing the reliability essential for robust and repeatable experimental data.

- Exceptional Stability: Immobilized molecules remain highly active and stable over a wide range of environmental conditions, including varying pH, ionic strength, and detergent concentrations, extending the practical shelf-life and reliability of your assays.

Our Microplates Coating Development Services

Creative Biolabs provides comprehensive, customized microplate coating development services, meticulously engineered for your specific analytical methods. We move beyond generic solutions, focusing on precision surface engineering through sophisticated chemical modifications and strategic polymer incorporation. Our expert team collaborates closely to identify optimal coating chemistries, ensuring maximum ligand immobilization, minimal non-specific binding, and robust assay performance for challenging targets. This bespoke approach guarantees your microplates are perfectly optimized for unique diagnostic or research applications, delivering consistent, reliable results.

Service Workflow of Microplates Coating Development

Our microplate coating development projects follow a structured, step-by-step workflow to ensure client satisfaction and optimal results:

We begin with a thorough discussion to understand your specific assay requirements, including the target molecule, desired immobilization chemistry (e.g., covalent, affinity-based), assay format (e.g., ELISA, cell-based), and performance metrics (e.g., sensitivity, dynamic range).

Our experts conduct a detailed feasibility assessment, identifying potential coating polymers (e.g., poly-NPEDMA derivatives, streptavidin, protein A/G) and surface activation chemistries that best suit your target molecule's properties and the analytical method.

We then proceed with laboratory-scale coating of prototype microplates. This phase involves iterative optimization of coating parameters such as concentration, incubation time, temperature, and blocking agents to achieve optimal ligand immobilization and minimal background.

Coated prototypes undergo comprehensive quality control. This includes assessing coating uniformity, binding capacity (e.g., using labeled ligands), specificity (e.g., cross-reactivity tests), and stability under various storage and assay conditions.

Upon successful validation, we transition to larger-scale production of your custom-coated microplates. The final delivery includes the optimized plates, along with detailed protocols, quality control reports, and ongoing technical support to ensure seamless integration into your laboratory workflow.

Applications

In Vitro Diagnostics

Drug Discovery and High-Throughput Screening

For pharmaceutical research, our microplates facilitate robust high-throughput screening of drug candidates. They provide consistent surfaces for ELISA, cell-based assays, and biochemical interaction studies, accelerating the identification of promising compounds by ensuring reliable binding and minimal variability across large screens.

Immunological Assays

The coated microplates are optimized for a wide array of immunological assays, including traditional ELISA, competitive immunoassays, and multiplexed bead-based assays. They ensure efficient and stable immobilization of capture antibodies or antigens, leading to enhanced signal-to-noise ratios and improved detection limits for various immune responses.

Nucleic Acid Hybridization Assays

In molecular diagnostics and genomics, our specialized coatings enable the efficient and specific capture of DNA or RNA targets for hybridization assays. These plates are invaluable for gene expression profiling, pathogen identification, and genetic screening, providing a reliable platform for precise nucleic acid detection and quantification.

Published Data

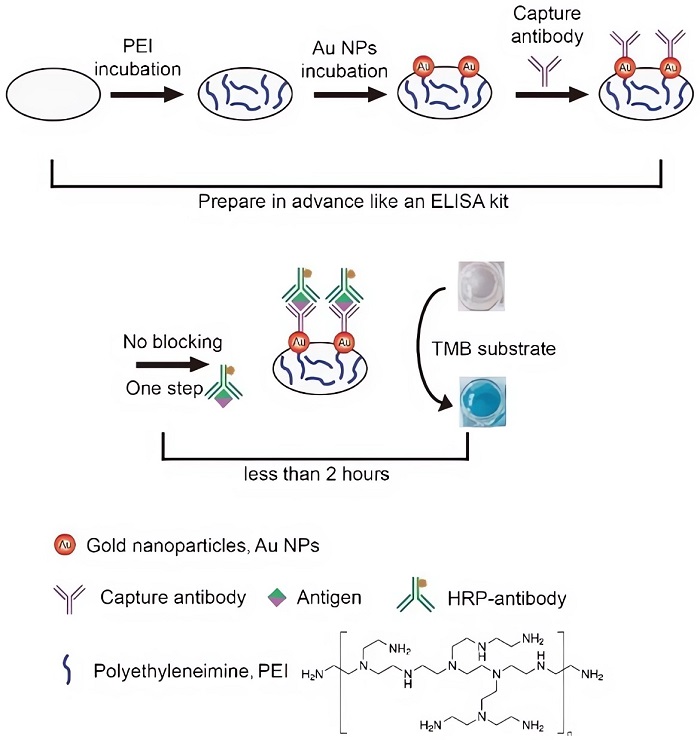

Fig.2 Schematic diagram of a PEI-GNP coated microwell plate.1

Fig.2 Schematic diagram of a PEI-GNP coated microwell plate.1

This research describes the development of a polyethyleneimine (PEI) gold nanoparticle (GNP) coated microwell plate for blocking-free ELISA. The study successfully showed that this novel coating prevented non-specific protein adsorption, significantly simplifying the ELISA workflow and reducing overall assay time to under two hours. The functionalized GNP layer improved signal amplification and lowered the detection limit for target biomarkers, showcasing the potential of advanced coatings to enhance diagnostic efficiency and sensitivity.

Service Highlights

- Custom Engineering: We meticulously engineer microplate surfaces using advanced chemical modifications. This service ensures high-density functional groups for optimal, uniform immobilization, enhancing assay performance.

- Superior Binding: Our service delivers coated plates with exceptional binding affinity for diverse biological molecules, including high-affinity biotin interactions, crucial for robust, specific molecular capture in high-performance assays.

- Guaranteed Stability: We assure that custom-coated microplates maintain uncompromising stability across various environmental conditions. This guarantees reliable performance and extended shelf-life, even with fluctuating pH, ionic strengths, or detergents.

- Expert Collaboration: Our expert team offers dedicated, bespoke coating solutions tailored to your unique assay requirements. We collaborate closely to develop application-specific coatings, ensuring optimal performance for challenging projects.

FAQs

-

Q: How does your microplate coating improve assay sensitivity compared to standard plates?

A: Our microplate coating significantly enhances assay sensitivity by presenting a higher density of uniformly distributed functional groups on the well surface. This increased density allows for the immobilization of a greater quantity of capture molecules, leading to a stronger signal upon target binding and thus enabling the detection of lower analyte concentrations.

-

Q: What types of molecules can be immobilized using your coating services?

A: Our coating services are versatile and capable of immobilizing a broad spectrum of biological molecules, including but not limited to antibodies, antigens, peptides, proteins, nucleic acids (DNA/RNA), and various enzymes. The specific coating chemistry is tailored to optimize the immobilization of your particular molecule of interest.

-

Q: Can your coated microplates reduce non-specific binding in my assays?

A: Yes, a primary advantage of Creative Biolabs' advanced coating technologies is the substantial reduction of non-specific binding. Our proprietary coating formulations are designed to create highly specific binding sites while simultaneously minimizing hydrophobic or charge-based interactions that lead to unwanted background signals.

-

Q: How do you ensure lot-to-lot reproducibility for your coated microplates?

A: Lot-to-lot reproducibility is ensured through a rigorous quality assurance program that encompasses every stage of our manufacturing process. This includes stringent control over raw material sourcing, standardized coating protocols, in-process quality checks, and comprehensive final product validation tests for each production lot.

-

Q: Are your coated microplates compatible with automated liquid handling systems?

A: Absolutely, our coated microplates are designed to be fully compatible with industry-standard automated liquid handling systems. Their precise dimensions and robust coating integrity ensure seamless integration into high-throughput automated workflows without compromising assay performance or plate integrity.

-

Q: Can I request a small batch of custom-coated plates for initial testing before committing to a larger order?

A: Yes, we understand the importance of preliminary testing. We offer the flexibility to provide small batches of custom-coated plates for initial validation and proof-of-concept studies. This allows you to evaluate the performance of our customized solutions in your specific assay before scaling up.

Leverage Creative Biolabs' years of specialized expertise in microplate coating to elevate your research and diagnostic capabilities. Our advanced solutions promise enhanced assay performance and unwavering reliability. Contact us today to discuss your specific needs and discover how our tailored services can accelerate your success.

Reference

- Huang, Ruijia et al. "Blocking-Free ELISA Using a Gold Nanoparticle Layer Coated Commercial Microwell Plate." Sensors (Basel, Switzerland) vol. 18,10 3537. 19 Oct. 2018, doi:10.3390/s18103537. Distributed under Open Access license CC BY 4.0, without modification.

For Research Use Only.