NanoReactor Technology for Continuous Precipitation of Micro- or Nanoparticles

After over a decade of development, Creative Biolabs has grown into a vaccine CRO/CDMO with excellent R&D and production capabilities. In addition to a wide range of technology platforms for vaccine research, we have conducted extensive and in-depth research on vaccine delivery technologies, as well as a series of highly efficient technologies. NanoReactor is one of them to ensure the satisfactory production of nano vaccines.

Background

The size of the nanoparticles is similar to the size of the cellular components, so they can enter the cells by pinocytosis mechanism. Nanotechnology in vaccinology is widely used both as a delivery system to enhance antigen processing or as an immunostimulatory adjuvant to activate or boost immunity. Nanoparticle types in nano-vaccinology mainly include polymer nanoparticles, inorganic nanoparticles such as gold nanoparticles, carbon nanoparticles, silicon nanoparticles, liposomes, immune stimulating complexes and the like. The preparation of nanoparticles mainly includes two major categories: physical methods and chemical methods. The pulverization method and the construction method are two major methods for physically preparing nanoparticles, and the gas phase reaction method and the liquid phase reaction method are two major methods for chemically synthesizing nanoparticles.

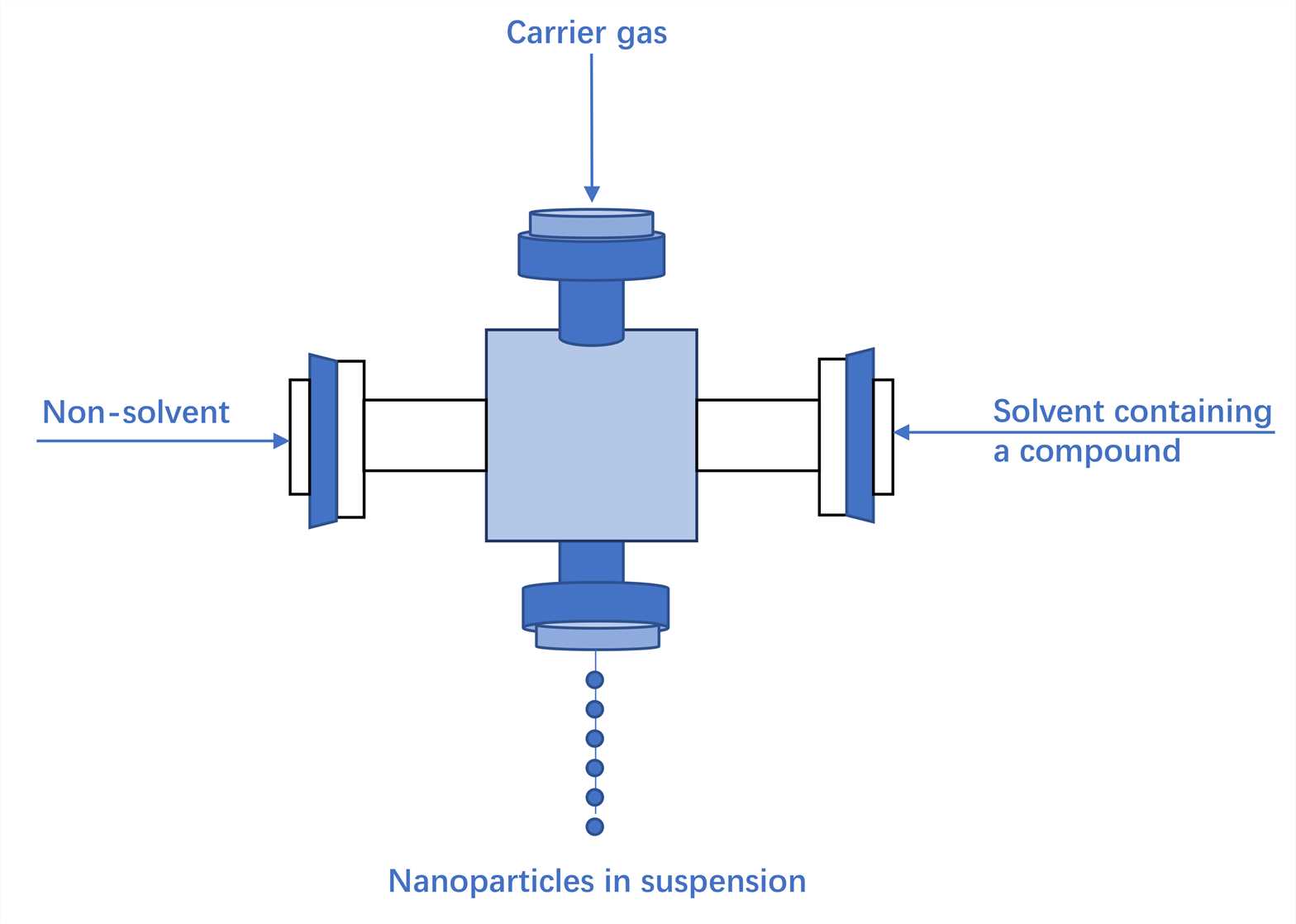

Fig.1 Schematic of NanoReactor.

NanoReactor Technology

To efficiently synthesize nanoparticles, the research team from Creative Biolabs developed the NanoReactor technology for continuous precipitation of microparticles or nanoparticles. This technology is achieved by solvent/non-solvent precipitation under controlled process conditions. At the heart of this technology is the NanoReactor, which has an edge that is only 3 cm long. In this apparatus, two opposite jets of a non-solvent and a solvent containing a compound are formed, and they collide in the cavity. The small diameter and high velocity allow the jets to mix the two liquids quickly and strongly, and the insoluble compounds are thus precipitated. The result is that the nanoscale particles are suspended in the liquid and can be applied to downstream processing.

Advantages of NanoReactor Technology

- Can be used for the production of various types of particles, such as coated nanoemulsions, nanoemulsions, multilayer nanoparticles, surface-stabilized polymeric nanoparticles, core-shell nanoparticles, surface-stabilized crystaline nanoparticles, and solid-lipid nanoparticles

- High-quality production of nanoparticles as well as complex drug delivery systems

- Good reproducibility

- The size of the produced particles can reach 5-1,000 nm or 10-50 μm

- Ability to meet all production needs from bench to commercial

- Fast and continuous precipitation speed of less than 0.1 ms, easier to integrate into downstream processes

Choosing the optimal vaccine delivery method can increase the efficacy of the vaccine to a greater extent. Nanoparticles are a commonly used vaccine delivery method, and this requirement places demands on the production technology of nanoparticles. Creative Biolabs, which has the world's top research team, has developed NanoReactor technology in this area through unremitting research and experimentation. If you have any needs in this regard, please contact us!

All of our products can only be used for research purposes. These vaccine ingredients CANNOT be used directly on humans or animals.