In the antibody development pipeline, a fast method to produce different kinds of antibodies simply with high quality is very important for structural and functional analysis. The cell-free system is becoming an attractive alternative method for antibody production because of its flexible properties and not limited by any cell membrane. At present, Creative Biolabs applies the cell-free expression system to the production of antibodies using B-cell sorting technology.

Background of Cell-free Systems

Cell-free protein synthesis, also known as in vitro translation, promotes the production of specific target proteins by utilizing translation mechanisms rather than using living cells. Therefore, antibody production and cell fate are separated, and the antibody protein synthesis reaction itself is not limited by the cell wall, which means that the reaction conditions can be entered from the outside of the reaction vessel. At present, the system has proved its potential as a reliable, multifunctional, and highly flexible antibody production platform, which can synthesize antibodies that are difficult to express.

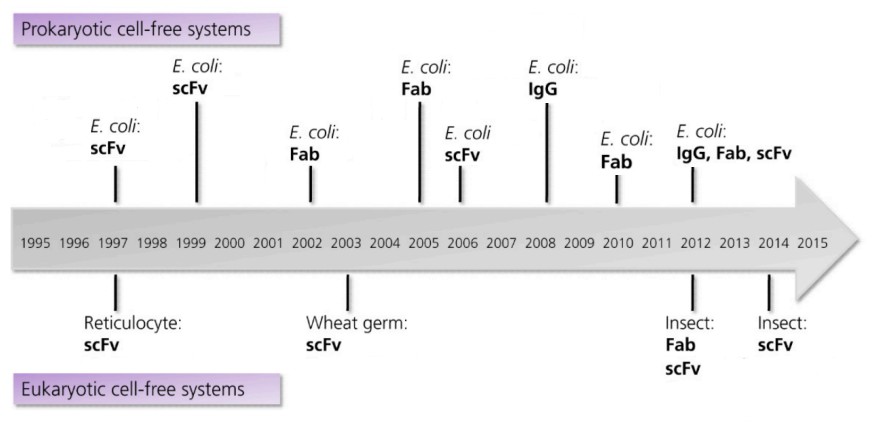

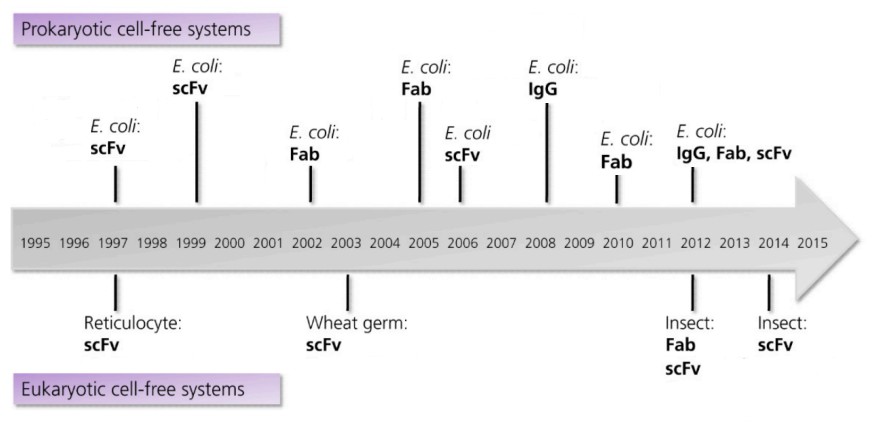

Fig.1 Overview of the production of antibodies in cell-free systems.1

Fig.1 Overview of the production of antibodies in cell-free systems.1

Operation Process of Cell-free Systems

Cell-free system is a rapid protein production system because it does not require transfection or cell culture and has no cell viability limitations. The cell-free system uses crude cell extracts prepared by lysing selected cells, followed by many washing steps to remove cell debris and genomic DNA. Such extracts contain all the main components required for transcription and translation. Therefore, Antibody production can be achieved by combining cell extracts with necessary substrates (such as amino acids, energy substrates, DNA, cofactors, salts, and nucleotides).

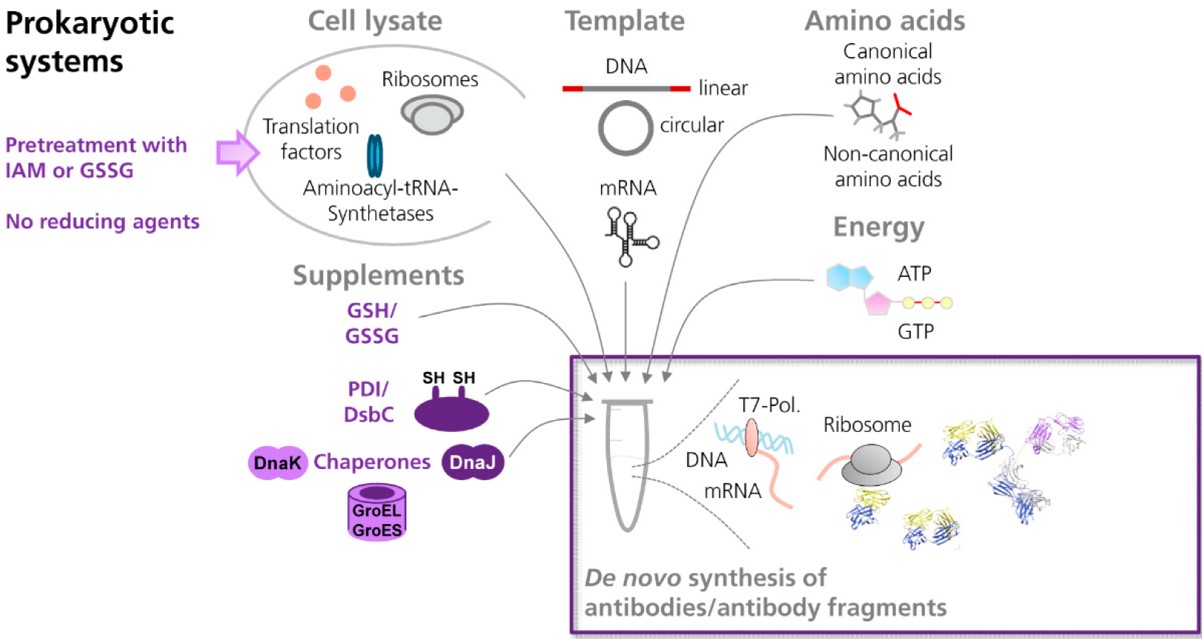

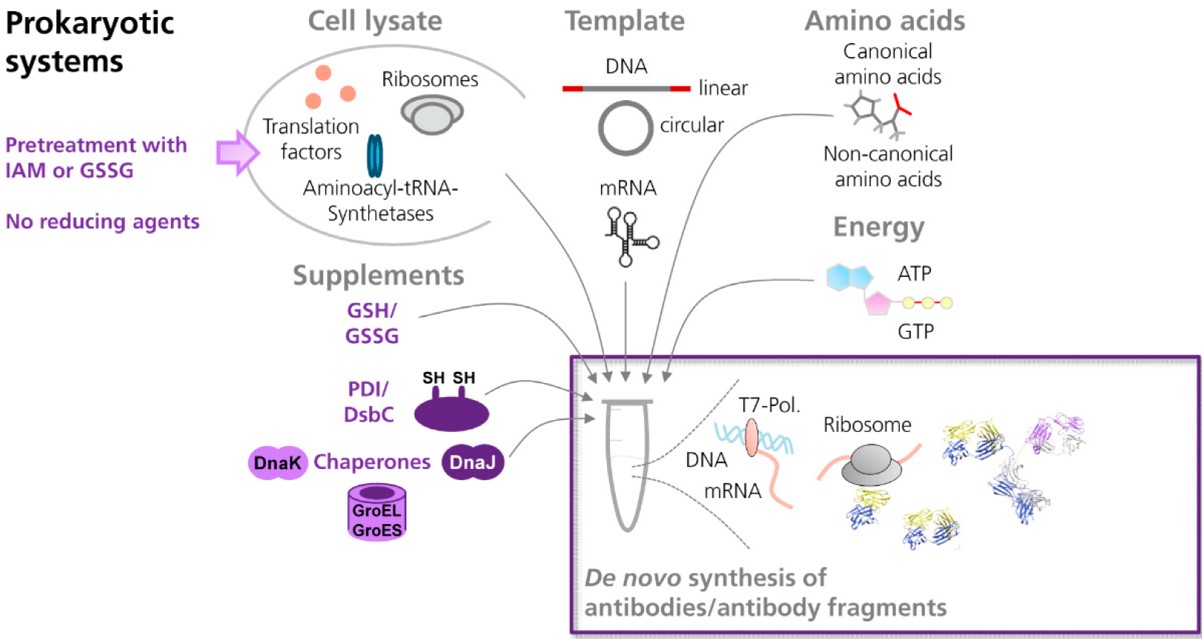

Fig.2 The overall process of cell-free antibody production in vitro translation systems.1

Fig.2 The overall process of cell-free antibody production in vitro translation systems.1

Advantages of Cell-free Systems

Compared with cell-based expression systems, the cell-free system has the following advantages:

-

By using cell-free technology, candidate antibodies can be rapidly synthesized within several hours of incubation time. Therefore, the information about gene design, expression titer, and antigen-binding characteristics is easier to obtain.

-

Cell-free reaction can be carried out in parallel, and hundreds of candidate antibodies can be screened simultaneously, which can be used for high-throughput production of antibody library and high-yield synthesis of selected target antibodies.

-

Due to the open reaction design, the cell-free system can be easily manipulated, and antibodies can be processed for downstream applications, such as purification and functional analysis, without transfection, selection, and clone amplification.

As part of the Native™ antibody discovery, Creative Biolabs provides several different types of cell lysates for the expression of cell-free antibodies, including prokaryotic cells and eukaryotic cells, such as Escherichia coli, wheat germ, rabbit reticulocytes, insect cells (such as Sf9 or Sf21) and human cell lysates. According to the biochemical characteristics of the antibody and its final application, the appropriate cell-free system can be selected. For more detailed information, please feel free to contact us or directly sent us an inquiry.

Reference

-

Stech, Marlitt, and Stefan Kubick. "Cell-free synthesis meets antibody production: a review." Antibodies 4.1 (2015): 12-33. Distributed under Open Access license CC BY 4.0. The image was modified by extracting and using only part of the original image.

For Research Use Only. Not For Clinical Use.

Related Sections:

ONLINE INQUIRY

Fig.1 Overview of the production of antibodies in cell-free systems.1

Fig.1 Overview of the production of antibodies in cell-free systems.1

Fig.2 The overall process of cell-free antibody production in vitro translation systems.1

Fig.2 The overall process of cell-free antibody production in vitro translation systems.1