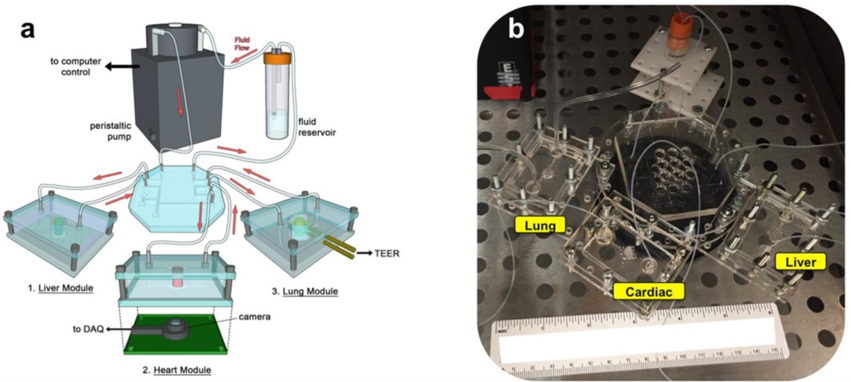

At present, iPSC for 3D bio-printing technology is mainly used in drug testing, through the cultivation of organ-on-a-chip to test the effectiveness and toxicity of drugs. Due to the complex functions of human organs, many drugs showed significant efficacy in animals but failed in clinical trials since organs in the human body may accidentally digest, swallow, or even degrade the medicine. A very meaningful technology, integrating human tissue into a microfluidic device to simulate human blood runoff from various organs, not only avoids animal experiments and human experiments that are ethically controversial, and saves the cost of clinical trials, but it can also better eliminate drug toxicity and find more effective drugs or treatment strategies to truly benefit patients.

iPSC for 3D bio-printing refers specifically to the process of manipulating iPSC cells to print active three-dimensional (3D) structures, which is also called cell printing, or organ printing. The technology to transform iPSC cells into most known cell types is well-established. As iPSC technology is more suitable for large-scale commercial production and saves time and cost to a great extent, the future of iPSC for 3D bio-printing technology has a bright future.

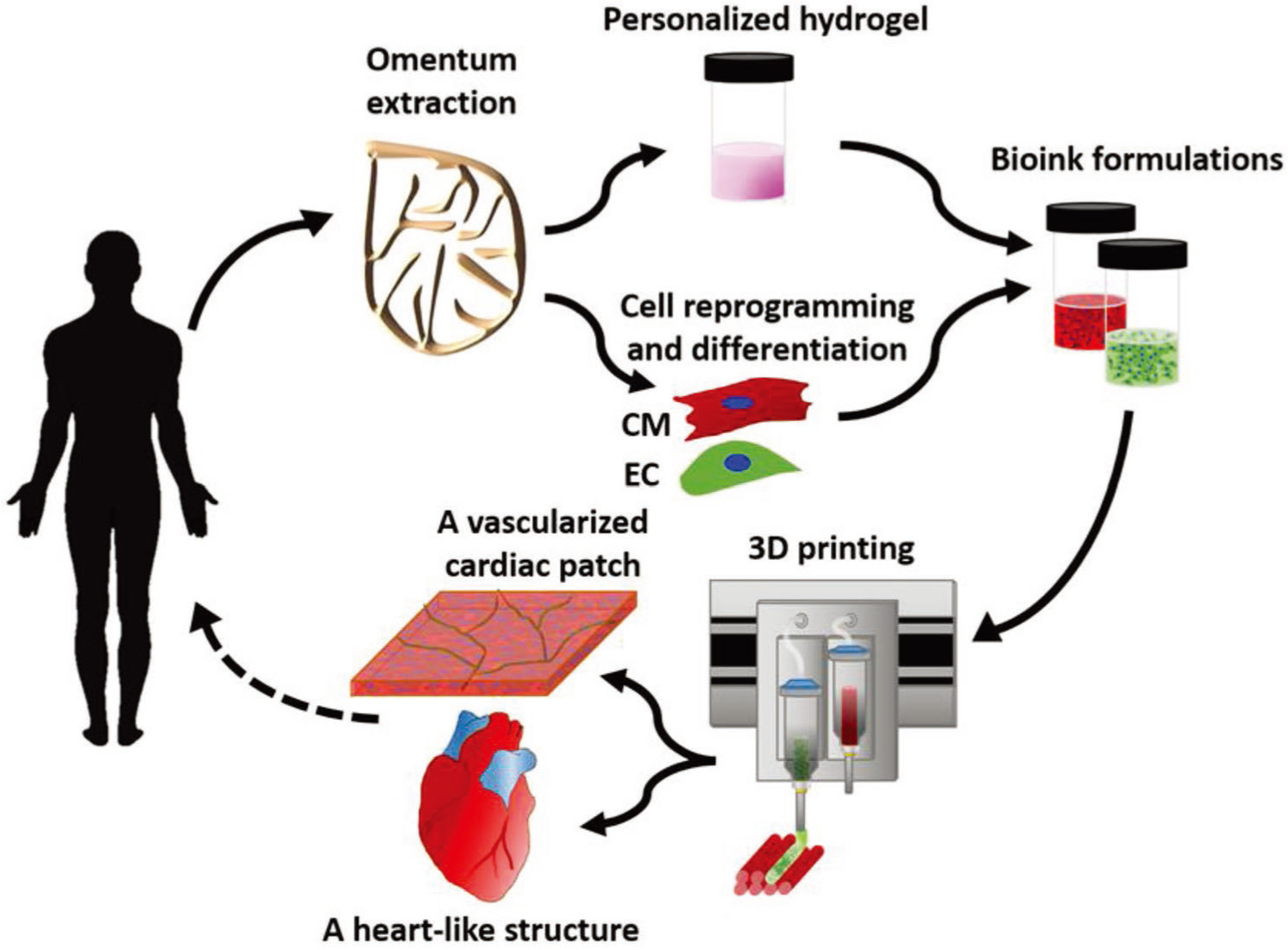

It is reported that a heart through 3D bio-printing technology has been successfully generated using iPSCs derived from the patient's fat cells. Specifically, the researchers firstly separated the cells and matrix in the collected fat tissue from the patient. These separated cells were then reprogrammed in vitro to obtain iPSCs. Then these iPSCs are differentiated into cardiomyocytes and vascular endothelial cells. The extracellular matrix such as collagen and glycoprotein in the patient's adipose tissue was processed into the hydrogel. Finally, cardiomyocytes and vascular endothelial cells derived from iPSCs were mixed with hydrogel for 3D bio-printing. In the process of obtaining materials, both iPSCs and hydrogel were derived from the patient's somatic cells, which can avoid immune rejection after transplantation.

Fig.1 The heart derived from the 3D bio-printing of iPSC.1

Fig.1 The heart derived from the 3D bio-printing of iPSC.1

Another breakthrough is the production of the bioengineered spinal cord using iPSC for 3D bio-printing technology. These scientists combined advanced cell bioengineering technology and unique 3D bio-printing technology. The spinal cord neuron progenitor cells (SNpcs) and oligodendrocyte progenitor cells (OPCs) derived from iPSCs were accurately printed layer by layer into the scaffold to form a bioengineered spinal cord by the biological 3D bio-printing equipment. The 3D printed sNPCs can differentiate and extend axons in the micro-scaffold channel to form a neuronal network. Calcium flux studies confirmed that these neuronal networks were active. This new technology is expected to help those who have long suffered from spinal cord injuries. The 3D printed bioengineered spinal cord can be surgically implanted into the injured area of the patient's spinal cord, acting as a "bridge" between nerve cells and the injured area, helping to rebuild axon connections. Although this method may not allow patients to walk again, it will relieve their pain and help them restore certain functions, such as the ability to control muscles and bladder.

Currently, there are three main methods:

1. Extrusion-based bioprinting (EBB)

EBB is currently the most commonly used 3D bio-printing technology in research and industry. EBB uses biological "ink" (a material that simulates the internal environment of living beings and supports cells) to generate pressure by motor or pneumatic means to squeeze the "ink" out of the needle.

2. Droplet-based bioprinting or inkjet (DBB)

The working principle of DBB is similar to the inkjet printer (inkjet) used in daily life. Biological "ink" is printed out in drops, and the number of nozzles is usually large to increase the printing speed. There are three common inkjet methods: piezoelectric effect (piezoelectric), thermal (thermal), and pneumatic (Pneumatic). The three methods all spray drop-like "ink" by changing the pressure. Droplet jet printing ejects one drop of "ink" at a time, while extrusion printing is a continuous strip shape.

3. Laser-based bioprinting (LBB)

Laser-assisted bioprinting (LBB) uses photopolymerization lasers to create cross-links containing cellular polymers to harden into solids. Due to the use of laser projection, the accuracy is high and complex shapes and structures can be printed. There are two common forms of LBB, one is LIFT (laser-induced forward transfer). The principle is to reflect the laser onto a layer of biological material containing cells, and the part irradiated by the laser will form a liquid. Drop down and scan different areas by laser to form the desired shape. The other is digital light printing (DLP). The principle is to reflect laser light onto biological materials through tens of thousands of digital micromirrors (DMDs). By changing the angle of each mirror, it can reflect with high precision. With a high-degree pattern, the material that is reflected by the light will harden to form the final desired shape.

Fig.2 Photograph of the modular multi-tissue organ-on-a-chip hardware system.2

Fig.2 Photograph of the modular multi-tissue organ-on-a-chip hardware system.2

In all, the main purposes of iPSC for 3D bio-printing is to solve the problem of the limited source of transplanted organs. The current organ transplantation can only be achieved through organ donation. For patients, organ transplantation not only takes much time to wait; even after successful transplantation, there will be long-term immune rejection. The emergence of iPSC for 3D bio-printing technology is expected to solve this problem and save many lives. If you'd like to know more about our stem cell service, please directly send us an e-mail or contact us for your special requests. Creative Biolabs will assist you in the whole development of iPSC (not limited to Reprogramming, Culture, Genetical Modification, Differentiation, and Characterization).

References

For Research Use Only. Not For Clinical Use.