Organ-on-a-Chip Overview

Organ-on-a-Chip (OoC) is a new approach for in vitro models to enhance organ/tissue physiological modeling, departing from the two-dimensional (2D) cell culture and animal models. An OoC is a microfluidic culture system that mimics the in vivo microenvironment of human organs or tissues. The micro-engineered system consists of microfluidic channels, living cells, and specialized scaffold (usually biomaterials) to simulate organ-specific functions, tissue-tissue interfaces, and dynamic factors like flow, mechanical strain, and chemical gradient in a physiological state. The most significant advantage of OoCs is that they can connect the in vitro and in vivo domains. Unlike 2D cell cultures, 3D OoCs can recreate cellular interactions, 3D architecture, and mechanical environment of native tissues.

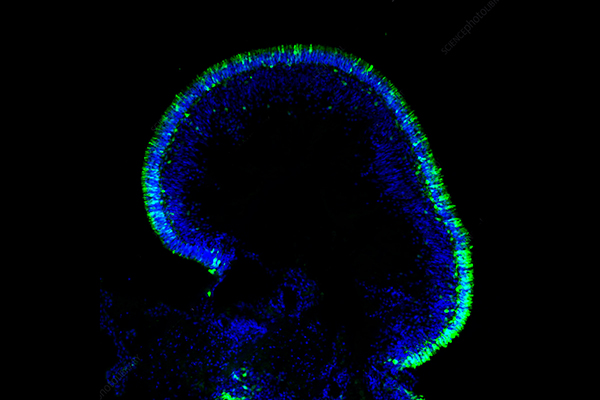

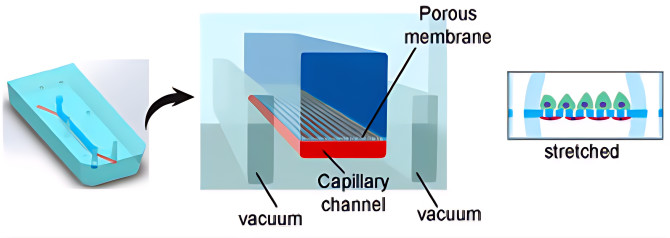

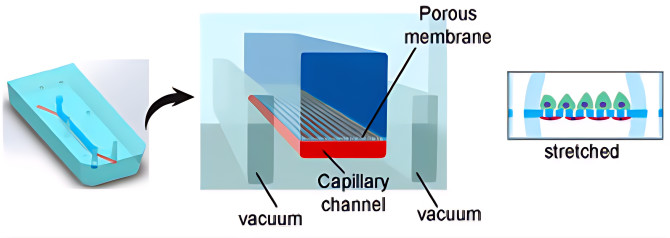

Figure 1 Kidney-on-a-chip design.1,3

Figure 1 Kidney-on-a-chip design.1,3

Biomaterials for Organ-on-a-Chip Introduction

Biomaterials are the substrates used to culture cells and build tissue. Biomaterials are important in tissue engineering because they create a biomimetic microenvironment that is similar to the extracellular matrix of the native tissue. Biomimetic properties include the ability to give mechanical cues, biochemical signals, and a physical architecture that can provide cell adhesion, proliferation, differentiation, and function. For an OoC to function correctly there are a few biomimetic properties that the biomaterial should exhibit. The material should be biocompatible and ensure that it does not affect cell proliferation and activity. The material should also be able to be tuned to have mechanical properties that mimic the tissue it is trying to imitate because cells will react differently to different material stiffness. Neurons grow on softer substrates while bone cells grow on stiffer substrates. The material should also be able to give chemical cues either through material properties or surface functionalization to allow for cell-cell and cell-matrix interactions.

Types of Biomaterials for Organ-on-a-Chip

The selection of biomaterials for OoC applications is diverse, encompassing a range of synthetic and natural polymers, hydrogels, and composites, each offering unique properties tailored to specific organ models.

|

Type of Biomaterial

|

Key Characteristics

|

Typical Advantages

|

Common Applications (in OoC)

|

|

Synthetic Polymers

|

|

Polydimethylsiloxane (PDMS)

|

Elastomeric; transparent, gas permeable, tunable stiffness.

|

Excellent optical clarity, easy fabrication, mechanical flexibility.

|

Lung-on-a-chip, intestine-on-a-chip, general microfluidic platforms.

|

|

Poly (lactic-co-glycolic acid) (PLGA)

|

Biodegradable; tunable degradation rate.

|

Tunable degradation, good mechanical properties, FDA-approved.

|

Tissue engineering scaffolds, drug development, bone-on-a-chip.

|

|

Natural Polymers

|

|

Collagen

|

Major ECM component; fibrous, promotes cell adhesion.

|

Natural cell-binding sites, biodegradable.

|

Most OoC models requiring ECM mimicry, liver-on-a-chip, skin-on-a-chip.

|

|

Hyaluronic Acid (HA)

|

Glycosaminoglycan; highly hygroscopic, biocompatible.

|

Non-immunogenic, highly hydrated, supports cell proliferation.

|

Cartilage-on-a-chip, joint-on-a-chip, neural tissue models.

|

|

Alginate

|

Polysaccharide; forms hydrogels via ionic crosslinking.

|

Biocompatible, tunable stiffness, non-immunogenic.

|

3D cell encapsulation, bioreactors, basic organ models.

|

|

Hydrogels

|

|

Poly(ethylene glycol) (PEG) hydrogels

|

Synthetic, hydrophilic; forms hydrogels when crosslinked.

|

Tunable mechanical properties, inert, chemically modifiable.

|

General cell encapsulation, microfabrication of complex geometries.

|

|

Matrigel

|

Basement membrane extract; rich in ECM proteins.

|

Physiologically relevant, supports complex cell behaviors.

|

Tumor spheroid formation, vascularization models, general organoid culture.

|

|

Composites

|

|

Polymer-Ceramic Composites

|

Combines polymer flexibility with ceramic rigidity.

|

Enhanced mechanical properties, improved bioactivity.

|

Bone-on-a-chip, dental tissue models.

|

Fabrication Technologies: Biomaterials for Organ-on-a-Chip

The fabrication of biomaterials into functional OoC components involves a range of advanced microfabrication and biofabrication techniques, critical for achieving the desired multi-scale architectures and integrating cellular elements.

-

Soft lithography: Soft lithography is the most commonly used technique for PDMS based OoC devices. In this method, a master mold is made (e.g., by photolithography), on which liquid PDMS is poured. After curing, the mold is peeled off to produce a patterned flexible replica. This method is frequently used for the fabrication of microfluidic channels, chambers and surface patterns. The advantages of this technique are low cost, fast prototyping and scalability.

-

3D Bioprinting: Additive manufacturing or more specifically 3D bioprinting is commonly used to produce 3D tissue constructs in OoCs. 3D bioprinting involves the dispensing of bio-inks (a mixture of biomaterials and cells) layer-by-layer to form 3D tissue constructs. The most common techniques of 3D bioprinting are extrusion-based bioprinting, inkjet bioprinting and laser-assisted bioprinting. 3D bioprinting provides high spatial control over the placement of cells and biomaterials and also allows heterogeneous tissue constructs.

-

Electrospinning: Electrospinning is a technique that produces nanometer scale fibers that resemble the ECM. Solutions of polymers are pumped through a nozzle and a high voltage is applied between the nozzle and collector. The polymer electrospins into fibers. Non-woven mats of the fibers are produced and have a large surface area for cell adhesion and cell alignment, and are useful for vascular, muscle, or nerve tissue engineering in OoC platforms.

-

Microfluidic Integration & Assembly: Besides the manufacturing of the individual components, the assembly of the final device is important. The device components can be bonded (e.g. PDMS to glass or other PDMS layers), membrane integrated (e.g. porous polycarbonate or electrospun membrane), or actuators/sensors added. Surface modification (e.g. plasma treatment, chemical grafting) can be used to improve hydrophilicity, promote cell adhesion or to immobilize biomolecules onto the biomaterials. The main goal is to create a leak proof system where the cells can stay viable and active under dynamic flow.

Research Progress of Biomaterials for Organ-on-a-Chip

The field of biomaterials for Organ-on-a-Chip is evolving rapidly, driven by the increasing demand for more accurate and predictive in vitro models. Recent research progress is focusing on several key areas:

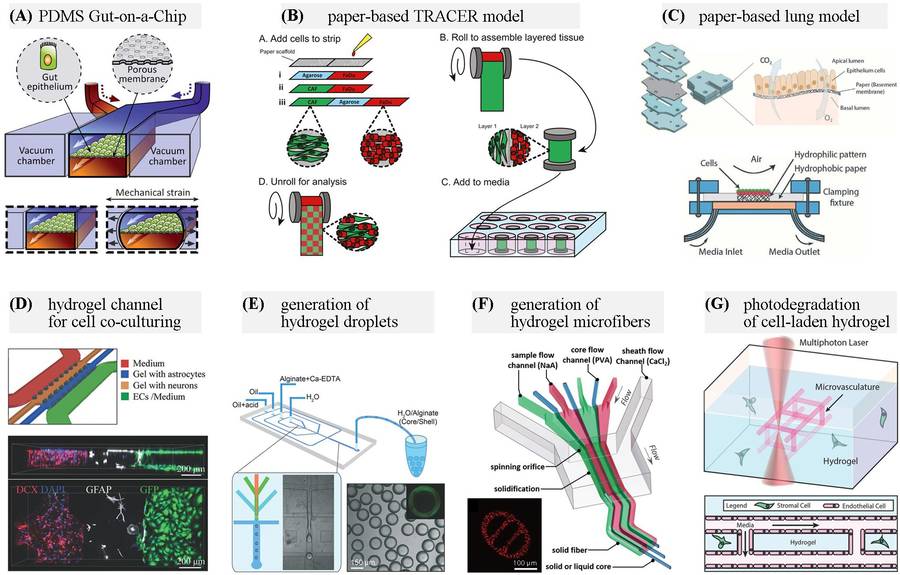

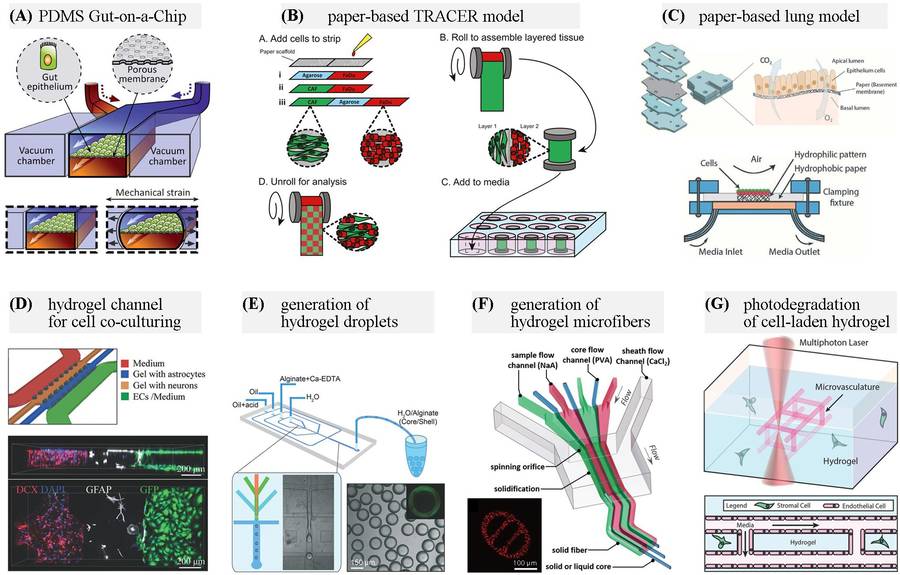

Figure 2 Representative materials used for OOC applications.2,3

Figure 2 Representative materials used for OOC applications.2,3

-

Development of "Smart" and Responsive Biomaterials

A key future trend is the emergence of smart materials that can sense and respond to external stimuli such as light or temperature, giving control over the mechanical properties of the material or release of drugs in a controlled manner, like biomimetic materials that are able to replicate the ways that living tissue reacts. For example, the photo-responsive hydrogels allow for the creation of biochemical gradients with precision.

-

Advanced ECM Mimicry

Tissue engineering researchers are developing materials that are as similar to the extracellular matrix (ECM) as possible in terms of composition and mechanical properties. Biomaterials with multiple ECM components, such as collagen and fibronectin, have been developed to control cell behavior more precisely.

-

Vascularization Strategies

Vascular networks are important for nutrient delivery in large tissue constructs. Examples of methods include addition of pro-angiogenic factors, co-culture with endothelial cells, and design of perfusable channels to allow for survival of tissue in Organ-on-a-chip applications.

-

Multi-Organ-on-a-Chip Systems

Multi-organ-on-a-chip systems are the interconnection of several organ models to study the effects on the system as a whole, such as systemic drug metabolism or disease progression. Biomaterials can provide the microenvironments that are required and fluidic interconnects between organs.

Frequently Asked Questions

Q: What are the future trends in biomaterials for Organ-on-a-Chip?

A: Emerging future directions for bio-materials are anticipated to include development of advanced composite biomaterials with finely controlled properties. Biomaterials which are able to replicate the dynamic and complex microenvironments in vivo will also become a focal point of future research. There will also be an increased interest in the interface of biomaterials with emerging technologies such as 3D bioprinting, artificial intelligence and machine learning.

Q: How do I ensure the biocompatibility of a new biomaterial for Organ-on-a-Chip?

A: Biocompatibility may be assessed in vitro by cell viability assays, cytotoxicity tests, and cell-adhesion studies. In vivo, animal models may be used to assess the biocompatibility of a new biomaterial by implanting the new biomaterial and observing any negative responses. Alternatively, comparison of the new biomaterial's properties and performance to well-established biocompatible materials can also be used to estimate the biocompatibility of the new material.

Q: Why are mechanical properties of biomaterials important in OoC modeling?

A: Mechanical properties (stiffness, elasticity, and viscoelasticity) are important because cells are highly mechanosensitive and respond to the physical properties of their environment (e.g., cell fate, cell migration, cell differentiation, and tissue organization). Biomaterials with tunable mechanical properties (e.g., crosslinking density in hydrogels) enable researchers to match the mechanical microenvironment of native tissues and thereby elicit the desired cellular response.

Overview of What Creative Biolabs Can Provide

At Creative Biolabs, we are at the forefront of advancing Organ-on-a-Chip technology through our comprehensive range of services and resources dedicated to biomaterials and OoC development. Leveraging our deep expertise in biomaterial science, tissue engineering, and microfluidics, we offer:

Creative Biolabs provides researchers with the tools and know-how to fully realize the potential of Organ-on-a-Chip technologies, ultimately enabling more effective drug candidates and a deeper understanding of human biology and disease. Contact us today to learn more!

References

-

Farhang Doost N, Srivastava S K. A comprehensive review of organ-on-a-chip technology and its applications. Biosensors, 2024, 14(5): 225. https://doi.org/10.3390/bios14050225

-

Ding C, Chen X, Kang Q, et al. Biomedical application of functional materials in organ-on-a-chip. Frontiers in bioengineering and biotechnology, 2020, 8: 823. https://doi.org/10.3389/fbioe.2020.00823

-

Distributed under Open Access license CC BY 4.0, without modification.

Research Model

Related Sections:

Figure 1 Kidney-on-a-chip design.1,3

Figure 1 Kidney-on-a-chip design.1,3

Figure 2 Representative materials used for OOC applications.2,3

Figure 2 Representative materials used for OOC applications.2,3