Custom Polymer-Enzyme Conjugation Service

Polymer-enzyme conjugates are molecular hybrid structures that combine the properties of enzymes and polymer molecules. The synthesis of such hybrids (or conjugates) is typically aimed at altering the physicochemical properties of enzymes. With extensive experience in polymer modification, Creative Biolabs offers its clients a comprehensive range of enzyme-polymer conjugation strategies. We focus on utilizing advanced conjugation technologies to produce a variety of biomolecules with polymer structures, including custom-developed polymer chains, polymer topologies, and conjugation structures.

What are Enzyme Conjugates?

Enzyme conjugates are molecular structures formed by covalently or non-covalently linking an enzyme with a carrier molecule (or payload). The fundamental goal of bioconjugation is to endow enzymes with new or improved properties without impairing their inherent catalytic function. The carrier molecule can be a small molecule (such as fluorescent dyes or haptens used for diagnosis) or a large molecule, such as antibodies, nucleic acids, nanoparticles, or the polymers mentioned in this article. This ingenious connection transforms normally easily degraded and eliminated natural enzymes into powerful and highly specialized biomolecular tools.

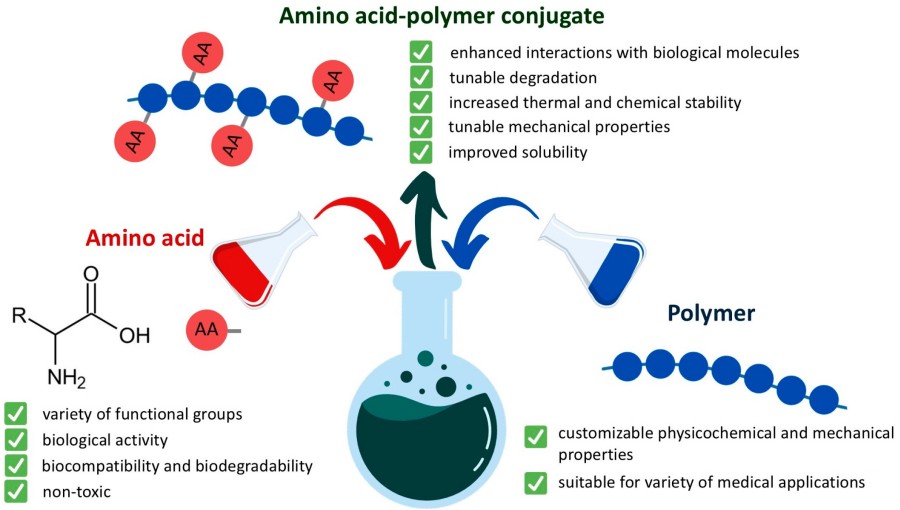

Figure 1. Graphical representation of polymer–amino acid conjugates.

Figure 1. Graphical representation of polymer–amino acid conjugates.

Polymer-Enzyme Conjugation Introduction

Polymer-enzyme coupling refers to the covalent attachment of one or more polymer chains to the surface of an enzyme. This process, often referred to as enzyme modification or polymer coating, is a highly complex form of biocoupling that utilizes the unique physicochemical properties of synthetic polymers to "modify" the environment surrounding the enzyme. The resulting polymer-enzyme complex (PEC) is a molecular chimera in which the enzyme retains its catalytically active sites, while the polymer component acts as a protective and functional shell, determining the stability, solubility, and in vivo behavior of the coupling. Various polymers have been investigated for this coupling reaction, including polyethylene glycol (PEG), hyaluronic acid, dextran, polyvinylpyrrolidone (PVP), polyvinyl alcohol (PVA), hydroxyethyl starch (HES), polyethyleneimine (PEI), and polyphosphates. The stabilizing effect of these polymers on the enzyme is mainly attributed to their shielding and protection of the enzyme from denaturing conditions.

Applications of Polymer-Enzyme Conjugates

The unique properties conferred by polymer conjugation have driven the widespread application of polymeric enzyme complexes (PECs) in biomedicine and industry.

Targeted Drug Delivery

PECs are a key component of antibody-guided enzyme prodrug therapy (ADEPT) systems. These systems are designed with a polymer-enzyme conjugate that allows for specific targeting of a site (e.g., a tumor). Upon targeting, the enzyme component activates a subsequently administered inert prodrug, converting it into a potent, locally active cytotoxic drug. This significantly improves efficacy while minimizing systemic toxicity.

Biosensors and Diagnostics

The superior stability of PECs under non-physiological conditions makes them ideal for the development of diagnostic assays and biosensors. Conjugated enzymes can be used to amplify signals or catalyze report reactions in devices such as blood glucose meters or lateral flow assays, exhibiting longer shelf life and good operational stability even in harsh environments.

Industrial Biocatalysis

In industrial applications, polymer-conjugated enzymes, especially those integrated into nanogels or solid supports, exhibit greater tolerance to organic solvents, high temperatures, and extreme pH values. This stability is crucial for continuous flow reactors and large-scale production processes, which often require harsh conditions.

Advantages of Polymer-Enzyme Conjugates

| Feature | Mechanism of Improvement |

|---|---|

| Prolonged Half-Life | Increased hydrodynamic radius prevents rapid renal filtration. |

| Reduced Immunogenicity | Polymer shell (e.g., PEG) sterically shields the enzyme surface from immune recognition. |

| Enhanced Stability | The polymer acts as a protective layer against denaturation by proteases, temperature, or pH changes. |

| Improved Solubility | Hydrophilic polymers enhance the water solubility of otherwise aggregation-prone enzymes. |

Tuning the Catalytic Performance and the Stability with Tailored Polymers

Strategic selection and design of polymer components allow for precise manipulation of conjugate properties to suit specific applications, and performance can be optimized through systematic polymer modification. Key factors influencing conjugate behavior include:

Molecular Weight

- Low molecular weight (5-10 kDa): Minimal impact on enzyme function; limited stability.

- Medium molecular weight (10-30 kDa): Balances activity retention and stability.

- High molecular weight (>30 kDa): Provides maximum protection but may reduce catalytic efficiency.

Structural Control

Advanced polymers (branched polymers, block copolymers) offer advantages such as enhanced shielding and targeting capabilities. Multi-arm polyethylene glycol (PEG) derivatives improve the protection of enzyme active sites, while block copolymers contribute to stability and targeting.

Smart Polymer Systems

Stimulus-responsive polymers, such as temperature-responsive and pH-responsive polymers, enable advanced control over enzyme activity. Innovations include polymers that respond to redox potential, light, or specific biomarkers, thereby enabling complex biocatalytic systems.

Conjugation Technology

Basic Conjugation Chemistry

The chemical basis of polymer-enzyme coupling lies in the formation of stable covalent bonds between functional groups on the polymer and complementary residues on the enzyme surface. Choosing an appropriate coupling chemical method is crucial, as it determines the specificity, efficiency, and structural integrity of the resulting conjugate. The most commonly used methods include:

- Amine Reaction Chemistry

Utilizing the abundant lysine residues on the enzyme surface, coupling is achieved using active esters (NHS, sulfonates), isocyanates, or aldehydes (for reductive amination). While this method is highly efficient, it often produces heterogeneous mixtures due to the presence of multiple modification sites.

- Thiol Reaction Chemistry

Targeting cysteine residues using maleimide, vinyl sulfone, or pyridine disulfide. This method offers higher specificity and yields more structurally defined conjugates when unique cysteine residues are present.

- Carboxylate Reaction Chemistry

Utilizing carbodiimide chemistry to activate aspartic acid and glutamate residues, enabling their coupling with amine-containing polymers.

More advanced strategies incorporate click chemistry principles, including copper-catalyzed azido-alkyne cycloaddition, strain-promoted azido-alkyne cycloaddition, and the anti-electron-demanding Diels-Alder reaction. These methods exhibit exceptional specificity, rapid reaction kinetics, and bioorthogonality—meaning they can be performed efficiently in biological environments without interfering with natural biochemical processes.

Site-Specific Conjugation Strategies

Precise spatial control of polymer linkages represents the cutting edge of coupling technology, overcoming the limitations of random modification. Several sophisticated methods enable this precision:

- Non-Natural Amino Acid Incorporation: Using engineered RNA synthetase pairs, specific residues can be introduced into predetermined positions within the enzyme sequence.

- Chemical Tagging Systems: Short peptide tags can be genetically engineered to fuse with enzymes, thereby providing specific recognition sequences for small molecule ligands pre-coupled to polymers.

Our Services

Creative Biolabs offers comprehensive, customized polymer-enzyme conjugation services designed to meet the diverse application needs of the biomedical, industrial, and research fields. Our services cover the entire development process from initial concept to large-scale production, providing integrated solutions to accelerate project progress and enhance technological outcomes.

Assembly of Nanobiocatalysts

Nanobiocatalysts can be prepared by conjugating enzymes to nanocarriers using conventional strategies, such as covalent coupling or encapsulation. The primary advantage of nanobiocatalysts is the exceptional enzyme loading capacity relative to the mass of the carrier material. This typically translates into superior catalytic efficiency and specific activity. Our custom development services for nanobiocatalysts include:

- Single-enzyme nanogels

- Dendrimers / Dendritic polymers

- Polymer micelles

- Nanoparticles

- Giant amphiphiles / Polymersomes

- MOF-enzyme nanohybrids

- Reverse micelles

Polymer Selection and Design

The strategic selection and design of polymer components are crucial factors determining the success of coupling. Our approach combines computational modelling, empirical data, and theoretical principles to determine the optimal polymer properties for each specific application.

Polyethylene Glycol and its Derivatives

We offer linear PEG, branched multi-arm PEG, and heterobifunctional PEG with a variety of reactive groups to meet specific coupling methods.

Stimulus-Responsive Polymers

These polymers include poly(N-isopropylacrylamide) (temperature-responsive), polyacrylic acid derivatives (pH-responsive), and polymers sensitive to redox potential, light, or specific enzymes.

Biodegradable Polymers

For applications requiring temporary modification, we offer polylactic acid (PLA), polyglycolic acid (PLA), and their copolymers, which degrade over time into non-toxic metabolites.

Functional Copolymers

We design advanced copolymers that combine multiple properties within a single polymer chain, such as PEG-PLA block copolymers that combine stealth and biodegradability, or charged copolymers that enhance solubility or promote complex coagulation.

What Makes Creative Biolabs Your Top Choice

Creative Biolabs sets itself apart in conjugation services through:

- ✅Integrated Expertise: A multidisciplinary team of specialists in enzyme engineering, polymer chemistry, analytical characterization, and regulatory affairs ensures comprehensive support throughout project execution.

- ✅Proprietary Technologies: We utilize advanced conjugation methodologies to enhance efficiency and precision, including a site-specific conjugation platform and directed evolution for optimal polymer selection.

- ✅Quality-First Approach: Rigorous quality control processes are in place at every stage, backed by advanced analytical techniques to ensure consistent performance.

Frequently Asked Questions

Q: How does polymer conjugation improve enzyme stability?

A: Polymer conjugation improves stability through several complementary mechanisms: (1) The polymer layer forms steric hindrance, reducing protease accessibility; (2) The polymer canopy stabilizes the native conformation of the enzyme by eliminating volume effects and surface modifications; (3) Charged polymers can create local microenvironments with optimized pH or ionic composition; (4) The polymer shielding layer reduces enzyme adsorption on container walls or interfaces; (5) For thermal stability, the polymer layer inhibits enzyme unfolding and aggregation pathways. The extent of stability improvement depends on the properties of the enzyme and polymer, typically increasing the enzyme's heat tolerance by 5-20°C and significantly extending its half-life under operating conditions.

Q: What is the typical timeline for custom conjugation projects?

A: We provide a detailed project plan with clearly defined milestones at project initiation and maintain regular communication to ensure timely completion. For urgent projects, we offer acceleration options, with feasibility assessments typically completed within 2-3 weeks.

Q: Can you conjugate polymers to any enzyme?

A: While our technical support supports conjugation with a wide range of enzymes, success depends on the specific characteristics of the enzyme, including structural stability, available modification sites, and sensitivity to structural perturbations. We conduct a comprehensive feasibility assessment for each new enzyme to identify potential challenges and develop appropriate strategies. In rare cases where direct conjugation encounters problems, we may recommend alternative methods such as enzyme engineering, encapsulation strategies, or vector-based immobilization. Our technical team provides honest assessments and advice during the project planning phase.

Conslusion

Creative Biolabs' custom polymer-enzyme conjugation services go beyond chemical reactions; they offer tailored biomolecular engineering solutions. Our profound understanding of the complexities of polymer science and bioconjugation chemistry helps clients overcome the inherent limitations of natural enzymes. Whether your goal is to develop long-acting therapies with superior pharmacokinetic properties or ultra-stable biocatalysts for industrial-scale production, our specialized platform provides high-purity, well-defined conjugates to help you succeed. Please contact us to discuss your demands or to request a proposal.

Reference

- Chrószcz-Porębska M, Gadomska-Gajadhur A. Cysteine Conjugation: An Approach to Obtain Polymers with Enhanced Muco-and Tissue Adhesion. International Journal of Molecular Sciences, 2024, 25(22): 12177. https://doi.org/10.3390/ijms252212177 Distributed under Open Access license CC BY 4.0, without modification.