Polymeric Microsphere-Based Delivery Strategies: Properties, Mechanisms, and Market Trends

Polymeric microspheres have revolutionized biomedicine by advancing the drug delivery efficiency. Their unique traits make them key for controlled and targeted therapy. In this article, Creative Labs will take you through the mechanisms, market trends, and properties of polymeric microspheres-based delivery systems.

Introduction to Polymeric Microsphere-based Delivery Systems

What Are Polymeric Microspheres?

Polymeric microspheres are micron-scale spherical carriers (typically <200 μm), which are engineered from natural, semi-synthetic, or synthetic polymers. They can be synthesized in the range of 1-1000 μm. As advanced carriers for targeted delivery, they possess several core properties that are defined by their polymer composition.

Biocompatibility

This can be granted by their polymeric nature. Natural polymers (e.g., chitosan, alginate) can minimize immunogenicity due to their biological relevance, while synthetic alternatives (e.g., FDA-approved PLGA) can mitigate cytotoxicity.

Biodegradability

The degradation process of natural polymers produces nontoxic byproducts, while synthetic polymers (e.g., PLGA, PCL) can be used to tune the degradation timeframes.

Controlled Release

The release profile of the loaded drug can be tuned to satisfy therapeutic needs through diffusion, polymer degradation, or swelling.

Targeting Ability

They can be used for targeted delivery via passive (EPR effect for tumors) or active (ligand-functionalized surfaces) targeting pathways.

Versatile drug compatibility

They are capable of encapsulating small molecules, peptides, nucleic acids, and antibodies, with designs (e.g., W/O/W emulsions) protecting labile agents, such as proteins, from degradation.

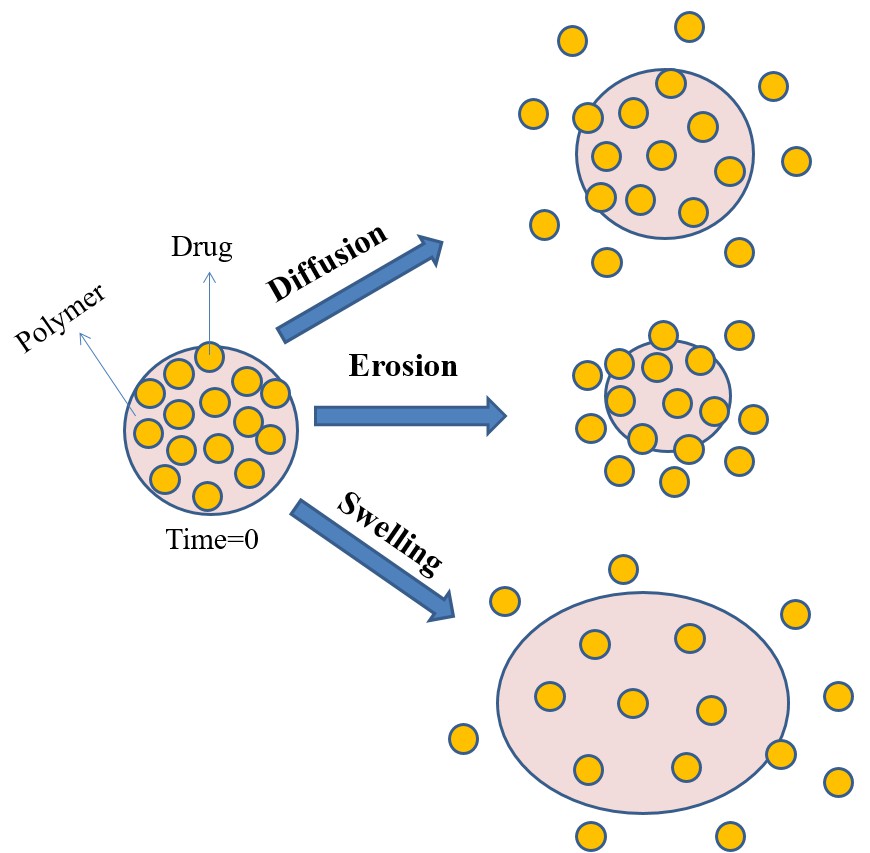

How Polymeric Microspheres Enable Controlled and Targeted Drug Release

Polymeric microspheres enable controlled drug delivery via four mechanisms: diffusion-controlled release, erosion-controlled release, swelling-controlled release, and mechanical disruption. These systems are designed to release active ingredients gradually, thus maintaining a therapeutic level of the drug in vivo for more extended periods (Figure 1).

Diffusion-controlled release

Under this process, encapsulated drugs (e.g., small-molecule chemotherapeutics) migrate from the higher-concentration areas within the microspheres to the lower-concentration surface via diffusion through the porous structure of the polymeric matrix. The diffusion rate is regulated by both the matrix density and the size of the drug. This mechanism is helpful in avoiding the initial burst effects.

Erosion-controlled release

Some polymers, such as chitosan or PLGA, break down via hydrolysis or enzymatic action over time, thus enabling the gradual release of embedded drugs as the microspheres disintegrate. This mechanism enables long-term and sustained drug release, leading to reduced dosing frequency and improved patient compliance.

Swelling-controlled release

As polymers, such as alginate or HPMC, can absorb gastrointestinal fluids to expand the matrix, therapeutic drugs can be released via the channels induced by the swelling matrix. This drug release mechanism is suitable for hydrophilic drugs or pH-sensitive applications. For instance, pH-responsive Eudragit-coated microspheres swell in the colon's neutral pH (as opposed to resisting swelling in the stomach's acidic environment), triggering the targeted release of antibiotics.

Mechanical disruption

Microspheres can be designed to release medication in response to mechanical deformation, such as shearing or compression pressures. This mechanism is influenced by several parameters, including specific medication, the preferred release profile, and the characteristics of the microspheres.

Fig.1

Drug delivery mechanisms of microspheres.2

Fig.1

Drug delivery mechanisms of microspheres.2

Emerging Applications: Gene and Protein Delivery

Microsphere technology is most widely used in gene and protein therapeutics.

One of the most exciting advances in Microsphere technology lies in gene and protein therapeutics. The traditional delivery of biomacromolecules, such as DNA, RNA, and proteins, faces challenges due to their instability and susceptibility to enzymatic degradation.

Polymeric microspheres overcome these barriers by:

- Shielding biomolecules from harsh biological environments.

- Allowing sustained, localized release of genetic material.

- Enabling non-invasive administration routes such as oral or transdermal delivery.

For example, PLGA-based microspheres have shown great promise in RNA interference (RNAi) and the encapsulation of vaccine antigens.

At Creative Biolabs, specialized microsphere-based delivery systems are designed to support emerging therapies, such as gene silencing and protein replacement, driving the future of precision biomedicine.

Nine Core Fabrication Techniques for Polymeric Microspheres

There are nine core fabrication techniques for polymeric microspheres. Each method is optimized to match specific drug properties (such as hydrophilicity and heat sensitivity) and meet particular application requirements (including scalability and targeting capabilities). For detailed information related to the polymeric microsphere formulation, please visit our Service Page (Polymeric Microspheres-based Delivery Systems).

Table 1. The core fabrication techniques for polymeric microspheres and their corresponding purposes.

| Fabrication techniques | Purpose |

|---|---|

| Emulsion-solvent evaporation | For the delivery of hydrophobic/hydrophilic drugs. |

| Spray drying | For rapid and scalable production. |

| Phase separation | For heat-sensitive agents. |

| Advanced microfluidics | For uniform particle sizes. |

| Microfluidic technology | For precise control of microsphere size and complex structures. |

| Solvent extraction | For shortened microsphere hardening time. |

| Wax melting | For basic controlled-release needs. |

| Freeze drying | For proteins or heat-sensitive drugs. |

| Ionotropic Gelation | For swelling-driven controlled drug release. |

Currently, polymeric microspheres are considered a cornerstone in modern biomedical research and pharmaceutical development. They are applied in a wide range of biomedical areas, including cancer, chronic diseases (such as diabetes and arthritis), tissue regeneration, and immunotherapy.

At Creative Biolabs, scientists specialize in developing polymeric microsphere-based delivery systems to improve the therapeutic efficiency. If you are interested, visit our service page for more information and schedule an appointment with our professionals.

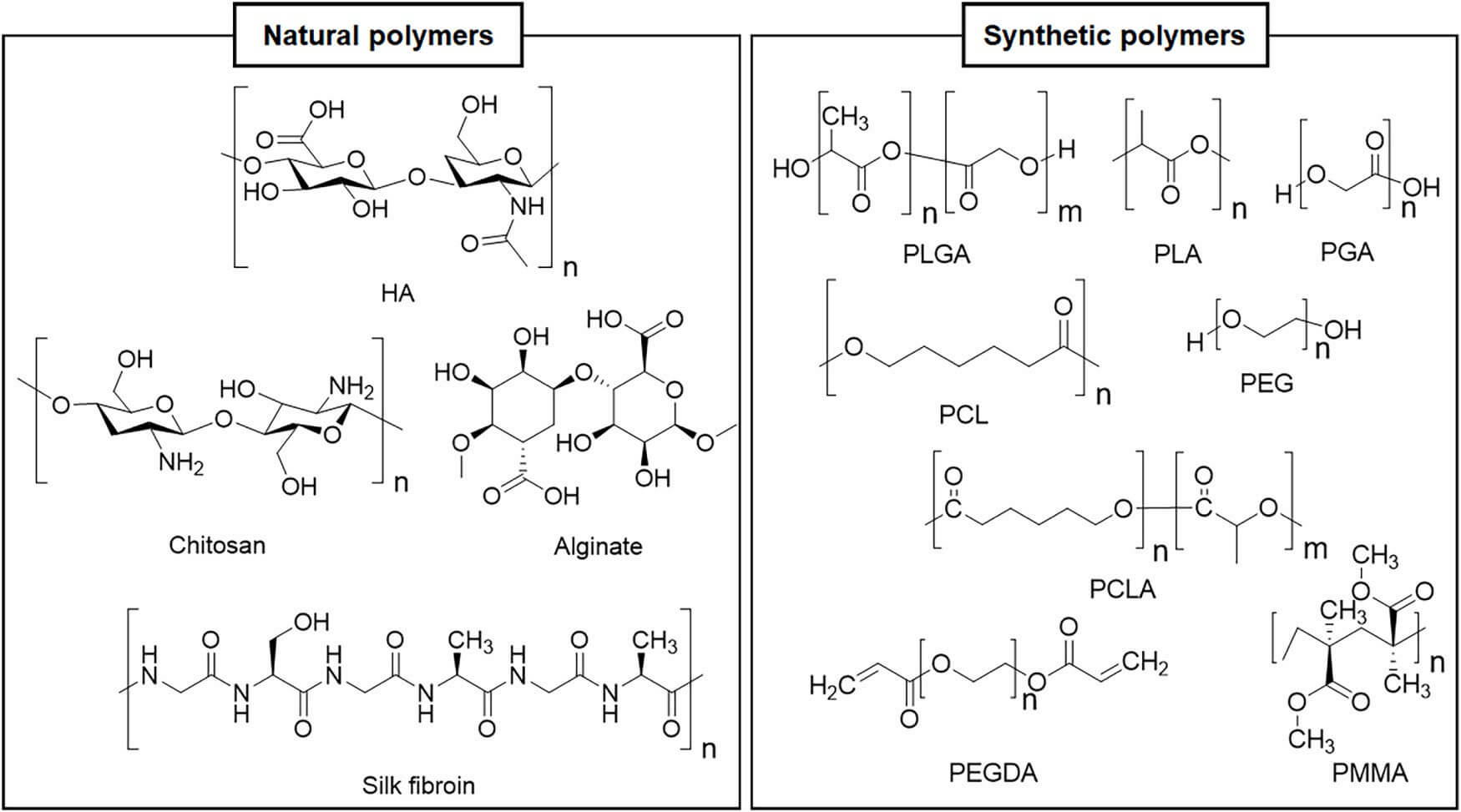

Key Materials Used in Polymeric Microsphere Formulation

As mentioned in the introduction, polymeric microspheres rely on careful selection of natural, synthetic, or semi-synthetic polymers as components to achieve biocompatibility, controlled drug release, and target-specific performance (Figure 2). These materials are tailored to the drug's properties (e.g., hydrophilicity, stability) and therapeutic goals (e.g., long-term release, localized targeting).

Natural Polymers

These polymers are derived from biological sources. Their biocompatibility and biodegradability endow the microspheres with diminished immunogenicity.

Chitosan

Chitosan is a cationic polysaccharide found in crustacean shells. It enables controlled drug release through interactions with anionic drugs. Moreover, it exhibits antimicrobial properties and supports tissue regeneration. Currently, chitosan is used to make microspheres for oral, nasal, and topical delivery (such as encapsulating metronidazole for periodontitis, or quercetin for diabetes).

Alginate

Alginate is extracted from brown algae. It can be used to form hydrogel microspheres via crosslinking with Ca2+. As its gelation properties can protect drugs (e.g., growth factors for wound healing) from gastric degradation, alginate is widely used for cell encapsulation and colon-targeted delivery.

Gelatin & Collagen

They are protein-based polymers that exhibit thermoreversible gelation (gelatin) or provide tissue-like structural support (collagen). They are often used in microspheres for sustained release of peptides (e.g., insulin) and tissue regeneration. However, their mechanical stability usually requires crosslinking (e.g., with glutaraldehyde).

Hyaluronic Acid (HA)

Hyaluronic acid (HA) is a glycosaminoglycan that is naturally found in connective tissue. It can retain water to form hydrated matrices. Hence, HA-based microspheres often exhibit enhanced mucosal adhesion properties and can be utilized in ophthalmic, joint, and skin delivery applications (e.g., dexamethasone for the treatment of rheumatoid arthritis).

Synthetic Polymers

Synthetic polymers are often used in applications that require long-acting or systemic delivery, as they offer tunable degradation rates and mechanical strength.

PLGA (Poly(lactic-co-glycolic acid))

In drug delivery, PLGA degrades into nontoxic lactic/glycolic acid. Its degradation rate can be adjusted via the LA: GA ratio (e.g., 50:50 for fast release, 75:25 for long-term release), making it suitable for chemotherapeutics and peptides.

PLA (Polylactide) & PCL (Polycaprolactone)

PLA, which is derived from renewable starches, can slowly degrade for sustained release in vivo. PCL, with ultra-long degradation times (months to years), is often used for long-term therapies, such as hormone delivery.

PEG (Polyethylene Glycol)

As a hydrophilic synthetic polymer, PEG can enhance drug solubility and reduce immunogenicity. PEG-modified microspheres (e.g., PLGA-PEG blends) exhibit enhanced in vivo circulation duration and improved passive targeting of tumor cells through the EPR effect.

Semi-Synthetic Polymers

They are cellulose derivatives (e.g., HPMC, carboxymethylcellulose) that can combine the natural and synthetic properties. They are biocompatible and stable in gastrointestinal environments, and can be used to modify release profiles (e.g., HPMC-coated microspheres for pH-sensitive colon delivery). These materials collectively enable polymeric microspheres to address diverse clinical needs, ranging from oral insulin delivery (using chitosan-alginate blends) to intra-articular anti-inflammatory therapy (utilizing PLGA-PCL microspheres).

Fig.2

Polymers commonly used in microsphere fabrication.5

Fig.2

Polymers commonly used in microsphere fabrication.5

Biodegradable vs. Non-Biodegradable Microspheres

Biodegradable microspheres are preferred for most pharmaceutical applications because they eliminate the need for removal after drug release. However, in biosensing and imaging applications, non-biodegradable polymeric microspheres are preferred. Selecting between biodegradable and non-biodegradable microspheres depends on the nature of the drug, treatment duration, and the required release profile (Table 2).

Table 2 The comparison between biodegradable and non-biodegradable microspheres.

| Feature | Biodegradable Microspheres | Non-Biodegradable Microspheres |

|---|---|---|

| Degradation | Naturally degrade in the body into nontoxic byproducts | Remain intact, requiring surgical or physical removal |

| Common Materials | PLGA, PCL, chitosan | Polystyrene, polymethyl methacrylate (PMMA) |

| Release Mechanism | Gradual through matrix breakdown | Controlled by diffusion through the intact shell |

| Application | Long-acting injectables, vaccines | Diagnostic imaging, implant coatings |

Manufacturing Challenges

Despite their advantages, the clinical application of microspheres presents challenges. One of the most significant challenges in the clinical translation of polymeric microspheres is the production of microspheres with consistency in particle size, encapsulation efficiency, and biocompatibility at large-scale production. Therefore, except for formulation optimization, industrial-scale microsphere production demands:

- Rigorous quality control;

- Sophisticated microfluidic or spray-drying equipment;

- High investment in Good Manufacturing Practice (GMP) facilities;

- Robust supply chain resilience to ensure material purity.

Global Market Overview: Size, Growth, and Trends

The global polymeric microspheres market was valued at USD 17.52 billion in 2025 and is forecasted to grow at a compound annual growth rate (CAGR) of 15.33%, reaching USD 47.54 billion by 2032. The robust continuous market growth is believed to be driven by three key factors:

- Rising demand for controlled-release pharmaceuticals.

- Expanding use in cosmetic, diagnostic, and industrial sectors.

- Advances in biodegradable polymer technology.

Currently, over 40% of the global polymeric microspheres market is covered by the pharmaceutical applications, where the demand for microsphere-based injectables and biologics delivery is increasing. In addition, Europe's tightening regulations on microplastics are fueling a shift toward sustainable and bio-based microspheres.

Future Directions: Regulatory and Sustainability Trends

A rising environmental consciousness is driving the microsphere market towards nontoxic and biodegradable products. The microplastics ban in the EU has already shrunk the CAGR of traditional polymer markets by 1.8%, urging manufacturers to use sustainable materials.

Emerging trends include:

- Bio-based polymer innovation (e.g., PLA, PHB).

- Greener synthesis methods minimizing solvent use.

- Adoption of circular economy principles for waste reduction.

At Creative Biolabs, we can help you actively integrate these sustainability principles into targeted delivery R&D, ensuring compliance with evolving regulatory landscapes while supporting your sustainable biopharma growth.

Related Services You May Be Interested in

FAQs

What benefits do polymeric microspheres offer for drug delivery?

Sustained and controlled drug release, increased bioavailability, and reduced side effects are some of the benefits.

What therapeutic areas benefit most from microsphere delivery systems?

Mainly oncology, vaccines, hormone therapy, and gene/protein therapies, where sustained drug action is vital.

How do biodegradable and non-biodegradable microspheres differ?

Biodegradable microspheres degrade naturally within the body, while non-biodegradable ones are designed for specific, non-degrading applications such as imaging or diagnostics.

Conclusion

Polymeric microspheres are revolutionizing drug delivery systems by enabling targeted, safe, and sustainable therapeutic outcomes. They stand out for their controlled release capabilities, biocompatibility, and versatile material options, making them a key component in next-generation pharmaceutical solutions.

Creative Biolabs leads in microsphere-based formulations and delivers innovative polymer synthesis with advanced delivery strategies spanning laboratory discoveries to clinical application. For more information related to polymeric microspheres, you could visit Creative Biolabs' Targeted Delivery Service Page (Polymeric Microspheres-based Delivery Systems) and make an appointment with our experts to design tailored microsphere-based systems for your research or therapeutic pipeline.

References

- Zhai, M., Wu, P., Liao, Y., Wu, L. & Zhao, Y. "Polymer Microspheres and Their Application in Cancer Diagnosis and Treatment." IJMS 25, 6556 (2024). https://www.mdpi.com/1422-0067/25/12/6556

- V V, N., Ahad, H. A., K V, H. K., Kotian, A. C. & Prasad, P. "Advancements in Optimizing Microsphere Preparation: A Comprehensive Review of Past Research Utilizing Factorial Design Methodology." Advances in Pharmacology and Pharmacy 13, 168–181 (2025). http://www.hrpub.org/journals/article_info.php?aid=14710 Distributed under Open Access license CC BY 4.0, without modification.

- Nikita Kerkar*, R. B. "A Comprehensive Overview of Microspheres as A Novel Drug Delivery System." International Journal of Pharmaceutical Sciences (2024). https://zenodo.org/doi/10.5281/zenodo.14187784

- Lengyel, M., Kállai-Szabó, N., Antal, V., Laki, A. J. & Antal, I. "Microparticles, Microspheres, and Microcapsules for Advanced Drug Delivery." Sci. Pharm. 87, 20 (2019). https://www.mdpi.com/2218-0532/87/3/20

- Lee, Y. J. & Kim, M. S. "Advances in drug-loaded microspheres for targeted, controlled, and sustained drug delivery: Potential, applications, and future directions." Biomedicine & Pharmacotherapy 189, 118244 (2025). https://linkinghub.elsevier.com/retrieve/pii/S075333222500438X Distributed under Open Access license CC BY 4.0, without modification.

- Hossain, K. M. Z., Patel, U. & Ahmed, I. "Development of microspheres for biomedical applications: a review." Prog Biomater 4, 1–19 (2015). https://oiccpress.com/pibm/article/view/10403

- Amoyav, B. & Benny, O. "Microfluidic Based Fabrication and Characterization of Highly Porous Polymeric Microspheres." Polymers 11, 419 (2019). https://www.mdpi.com/2073-4360/11/3/419