PLGA for Drug Delivery: A Simple, Practical Guide for Modern Drug Formulation

PLGA remains one of the most dependable materials in drug delivery, valued for its predictable behavior, safety, and strong regulatory track record. Its biodegradable structure supports controlled release across a broad spectrum of therapeutics—from small molecules to peptides, proteins, nucleic acids, and advanced biologics. This guide from Creative Biolabs walks you through how PLGA works, why it is widely used, and how it continues to shape modern formulation strategies. With clear explanations and real-world examples, this article highlights why PLGA remains a cornerstone for today's drug development teams.

Introduction: What Is PLGA and Why Is It Widely Used for Drug Delivery?

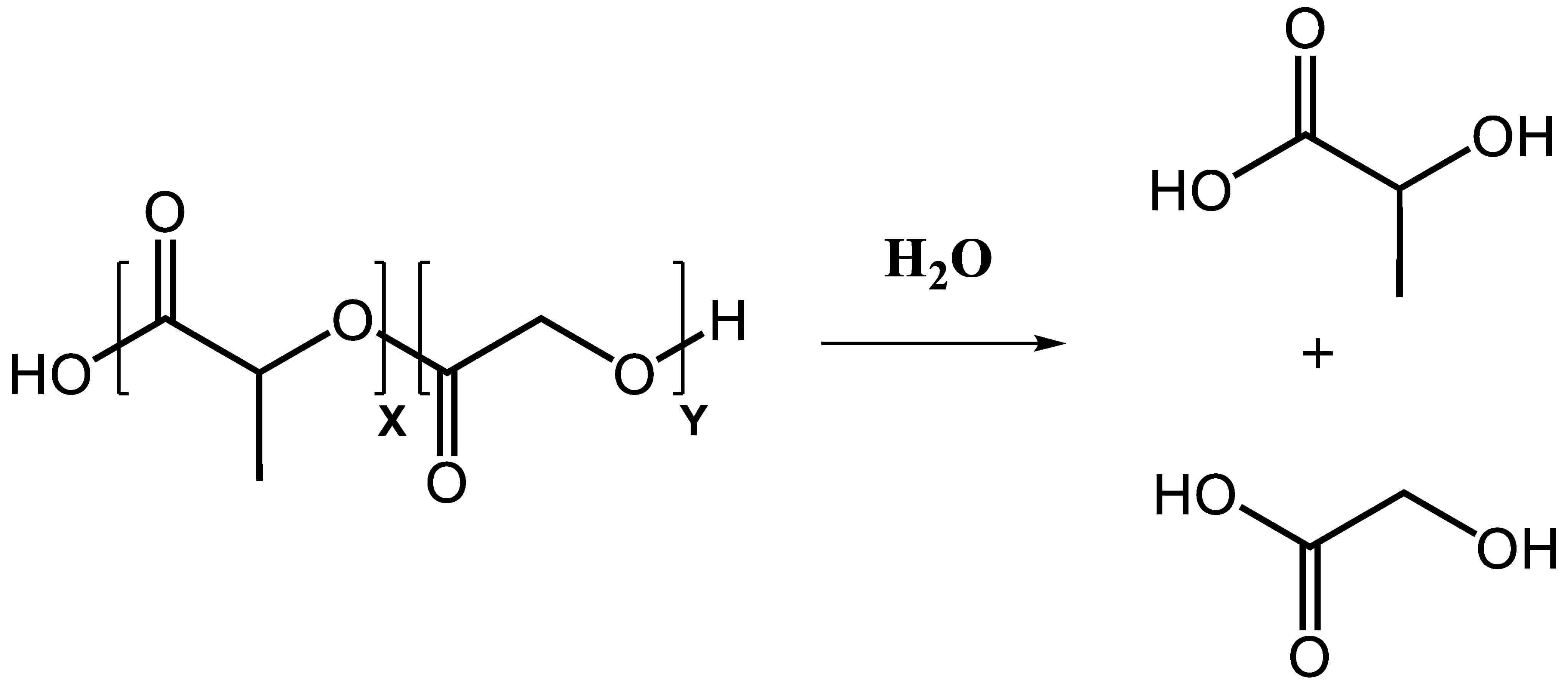

Poly(lactic-co-glycolic acid) (PLGA) is a synthetic biodegradable polymer generated by co-polymerizing lactic acid and glycolic acid (Figure 1). Because both monomers naturally exist in human metabolic pathways, PLGA breaks down into physiologically compatible products after administration.

Fig.1

PLGA hydrolysis into monomers, lactic acid and glycolic acid.1

Fig.1

PLGA hydrolysis into monomers, lactic acid and glycolic acid.1

Why PLGA is preferred:

- Biodegradable and biocompatible: Fully metabolized with no lasting residues.

- Regulatory-approved track record: Multiple marketed PLGA-based formulations.

- Versatile formats: Microspheres, nanoparticles, implants, and hydrogels.

- Controlled release: Tunable degradation enables extended, predictable drug exposure.

In practice, PLGA functions like a highly customizable container, protecting the cargo and releasing it in a controlled manner.

In short: PLGA for drug delivery combines safety, flexibility, and tunable release, which makes it a core material in modern controlled-release systems.

How PLGA Works in Drug Delivery: Degradation and Drug Release

PLGA's delivery performance is governed by two key processes: polymer degradation and drug release kinetics.

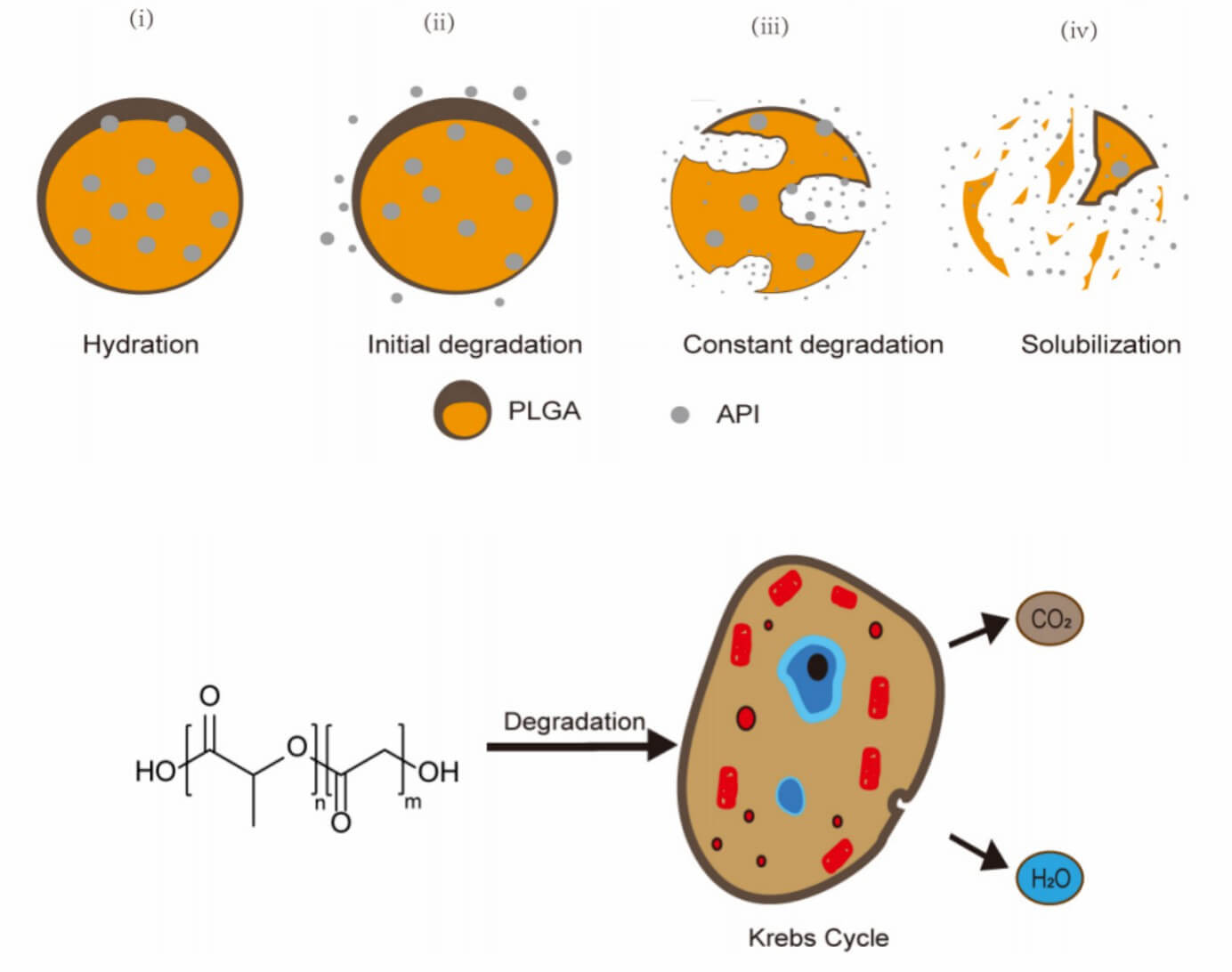

1. Hydrolysis and Degradation

Once inside the body, water penetrates the polymer matrix and gradually cleaves ester linkages through hydrolysis. The polymer first fragments into shorter chains and eventually into lactic acid and glycolic acid, which naturally enter the Krebs cycle (Figure 2).

- This clean metabolic breakdown is a major safety advantage.

Fig.2

PLGA in different degradation stages.5

Fig.2

PLGA in different degradation stages.5

2. Combined Drug Release Mechanisms

PLGA-based systems typically release drugs through a combination of:

- Diffusion through pores or channels.

- Polymer degradation, gradually exposing the payload.

- Matrix erosion, enabling complete release

By adjusting polymer composition, molecular weight, and morphology, developers can fine-tune the release rate, minimize initial burst, and extend therapeutic duration.

PLGA Properties That Matter for Delivery Performance

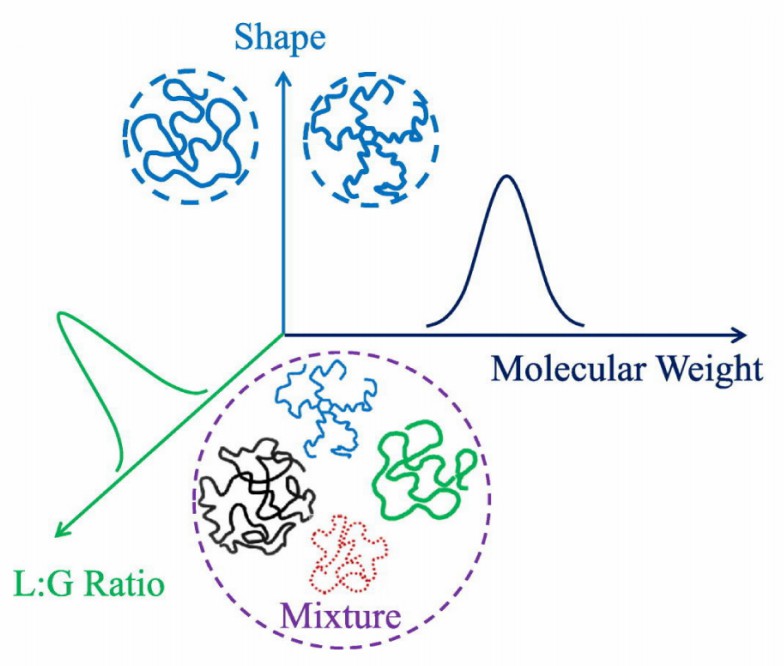

Different PLGA types behave differently. The most influential factors include the lactic: glycolic ratio, molecular weight, end-group chemistry, and surface characteristics. (Figure 3).

Fig.3

PLGA characterization involves assessing its molecular weight, L: G ratio, and shape.5

Fig.3

PLGA characterization involves assessing its molecular weight, L: G ratio, and shape.5

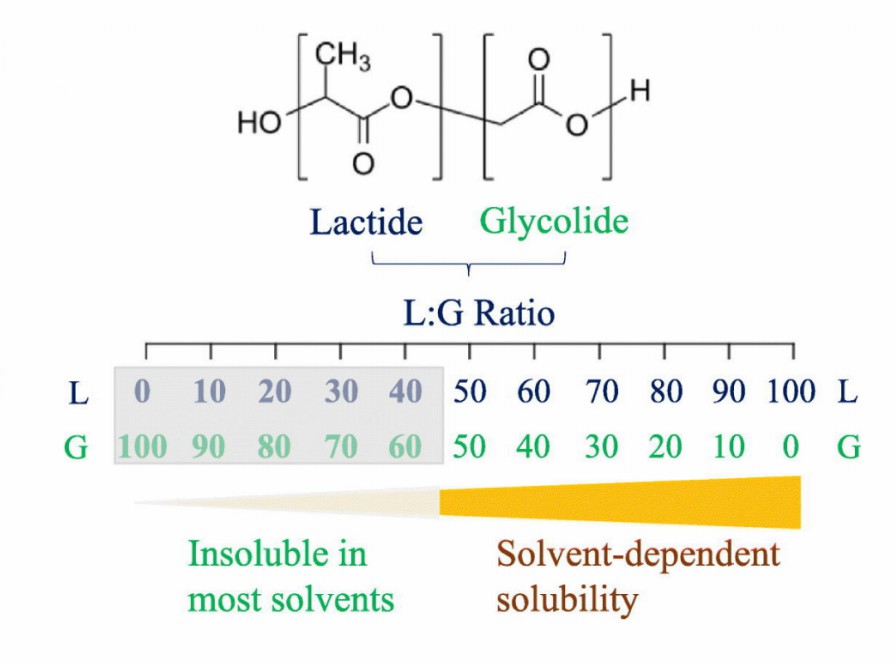

Lactic: Glycolic Ratio

The ratio of lactic acid to glycolic acid strongly affects degradation (Figure 4):

- Higher lactic content → more hydrophobic, slower degradation

- Higher glycolic content → more hydrophilic, faster degradation

Common ratios include 50:50, 65:35, 75:25, and 85:15.

- A 50:50 PLGA usually degrades the fastest.

Fig.4

Different solvation of PLGAs with varying L: G ratios.5

Fig.4

Different solvation of PLGAs with varying L: G ratios.5

Molecular Weight

- High molecular weight PLGA → stronger matrix, slower erosion, more extended release.

- Low molecular weight PLGA → weaker matrix, faster erosion, shorter release.

End Groups

The polymer may be acid-terminated or ester-terminated, which affects:

- Acid-terminated PLGA: Faster water uptake and degradation

- Ester-terminated PLGA: Slower initiation of degradation

Surface Charge

Surface charge influences cellular uptake, biodistribution, and protein adsorption, which are crucial for nanoparticle-based targeting strategies.

Together, these variables function like adjustable "release dials" that researchers can use to match the desired therapeutic profile.

PLGA vs. Other Biodegradable Polymers: PLA and PCL

When choosing a polymer, researchers often need to compare PLGA, PLA, and PCL. Table 1 contrasts these common biodegradable polymers, PLGA, PLA, and PCL, across four key features: degradation rate, hydrophilicity, release control, and regulatory experience. Due to their differences, PLGA, PLA, and PCL are used for depot injections/nanoparticles, implants/sutures, and long-term implants/scaffolds, respectively.

Table 1 Comparison of PLGA with PLA and PCL in four key features.

| Feature | PLGA | PLA | PCL |

|---|---|---|---|

| Degradation rate | Fast to medium (weeks–months) | Medium (months) | Slow (months–years) |

| Hydrophilicity | Moderate (tunable via ratio) | More hydrophobic | Hydrophobic |

| Release control | Highly tunable | Moderate | Better suited for a very long release |

| Regulatory experience | Very strong | Strong | Growing |

| Typical applications | Depot injections, nanoparticles, etc. | Implants, sutures | Long-term implants, scaffolds |

Because PLGA for drug delivery can be tuned across a wide range of release times, it is often chosen when developers need:

- Release over weeks to a few months

- Strong clinical and regulatory precedent

- Flexible formats (micro, nano, implant)

Looking to optimize PLGA's properties for your drug delivery product?

Share your payload type, desired release timeline, and target profile with our PLGA Formulation Experts. We will craft a tailored solution—including optimized L:G ratio, molecular weight, end-group selection, and polymer comparison (vs. PLA/PCL)—aligned with your product's needs.

PLGA Delivery Formats: Microspheres, Nanoparticles, Hydrogels, and More

PLGA, PLA, and PCL are all biodegradable polymers, but their degradation rates and release behaviors differ significantly.

PLGA Microspheres

- Small spherical particles, usually 1-100 µm in size

- Often used in injectable depot formulations

- Useful for monthly or quarterly dosing

Used in: hormone therapy, chronic pain management, oncology formulations

PLGA Nanoparticles

- Much smaller particles, often below 500 nm

- Can circulate in the bloodstream and reach deeper tissues

- Suitable for targeted and systemic delivery

Used for: anticancer drugs, vaccine carriers, nucleic acid delivery

PLGA Hydrogels and Implants

- Hydrogels are water-swollen networks that can be loaded with drugs.

- Implants are solid or semi-solid PLGA devices placed at or near the target site.

Suitable for: localized therapies, high-dose biologics, controlled-release regeneration tools

Real-World Applications of PLGA for Drug Delivery

PLGA's flexibility supports a broad spectrum of therapeutic needs:

Long-Acting Injectables

PLGA microspheres and depots allow:

- Weekly, monthly, or even longer dosing

- More stable plasma concentrations

- Better patient convenience and adherence

Cancer Drug Delivery

PLGA nanoparticles can:

- Carry hydrophobic chemotherapies

- Improve tumor targeting when combined with ligands

- Reduce peak toxicity by smoothing exposure over time

Peptides, Proteins, and Biologics

Proteins and peptides are often unstable in solution. PLGA:

- Protects them from rapid degradation

- Releases them slowly over weeks or months

- Supports more convenient dosing strategies

Gene and RNA Delivery

When PLGA is combined with other components, it can help deliver:

- DNA plasmids

- siRNA

- mRNA and other nucleic acids

This is especially useful when controlled release and local expression are needed.

Vaccines and Immune Modulation

PLGA particles can work as antigen carriers and sometimes as adjuvants, helping to:

- Control the timing of antigen exposure

- Enhance immune responses

- Reduce the number of required doses

Tissue Engineering and Regenerative Medicine

PLGA scaffolds are used as:

- Temporary support structures for growing cells

- Carriers for growth factors and signaling molecules

- Tools for guided tissue regeneration

Looking to harness PLGA's versatile applications for your drug product?

Share your therapeutic area (e.g., cancer, biologics), payload type, and delivery goals (e.g., long-acting, targeted) with our PLGA Drug Delivery Experts. We will design a tailored solution—including optimized PLGA format (nanoparticles, microspheres, etc.), formulation parameters, and regulatory-aligned design—matched to your product's unique needs.

Challenges of Using PLGA for Delivery

While poly(lactic-co-glycolic acid) (PLGA) stands as a gold standard in modern drug formulation for its biocompatibility and tunable release, it's not without practical hurdles that demand careful navigation. From unintended rapid initial drug release to challenges encapsulating sensitive molecules and scaling production reliably, these obstacles can impact therapeutic efficacy, safety, and regulatory compliance.

Burst Release

Some formulations show a rapid initial release of the drug:

- This can lead to higher early exposure.

- It may reduce the duration of steady release.

Researchers reduce burst release by:

- Optimizing particle size and structure

- Adjusting the lactic: glycolic ratio

- Using surface coatings or blending with other polymers

Encapsulation Efficiency

Hydrophilic drugs, proteins, and nucleic acids can be hard to encapsulate:

- They may escape during manufacturing.

- They can be damaged by solvent exposure or shear.

New techniques, including microfluidics, mild emulsification, and stabilizing excipients, are being employed to safeguard these sensitive molecules.

Manufacturing Scale-Up

Producing PLGA particles at an industrial scale is not trivial:

- Batch-to-batch consistency is critical.

- Particle size and distribution must be tightly controlled.

- Regulatory expectations around quality are high.

Advanced process controls, in-line analytics, and engineered microfluidic systems are helping to make production more robust and efficient.

Struggling with PLGA delivery challenges like burst release, low encapsulation efficiency, or scale-up hurdles?

Creative Biolabs is committed to delivering tailored, actionable solutions for your drug formulation needs. Share your payload type (e.g., biologics, hydrophilic drugs), target release profile, and production scale goals with our expert team. We will optimize PLGA particle design, refine encapsulation techniques, and implement robust process controls.

Future Directions: Smarter and More Targeted PLGA Systems

The next generation of PLGA for drug delivery focuses on more intelligent and more precise systems.

Key trends include:

- Targeted PLGA nanoparticles with ligands for specific cells or tissues

- Multi-drug loading, where two or more drugs are released on different timelines

- Stimuli-responsive PLGA systems, which respond to pH, enzymes, or the local environment

- AI-guided formulation design, used to predict optimal ratios and process conditions

- Microfluidic manufacturing for narrow size distribution and high reproducibility

Related Services You May Be Interested in

FAQs

What does PLGA stand for?

PLGA stands for poly(lactic-co-glycolic acid). It is a biodegradable copolymer made from lactic acid and glycolic acid, widely used in controlled drug delivery.

Why is PLGA used for drug delivery?

PLGA is used because it is biodegradable, biocompatible, and tunable. It can protect drugs and release them in a controlled way over weeks or months.

What types of drugs can PLGA deliver?

PLGA can carry small molecules, peptides, proteins, nucleic acids, and vaccines. This makes it suitable for many injectable and implantable therapies.

What are PLGA microspheres and nanoparticles?

PLGA microspheres and nanoparticles are drug-loaded particles made of PLGA. They allow controlled and often long-acting drug release after injection or implantation.

How long does PLGA take to degrade in the body?

The degradation time of PLGA can range from approximately 2 weeks to 6 months, depending on the lactic: glycolic ratio, molecular weight, and formulation design.

Is PLGA safe and biocompatible?

Yes. PLGA has a strong safety record and breaks down into lactic and glycolic acids, which are naturally processed by the body under normal conditions.

How does PLGA compare to PLA or PCL in delivery applications?

PLGA generally degrades faster than PLA or PCL, giving more flexible control over release times. PLA and PCL are better when a very long-term release is required.

Conclusion: Why PLGA for Delivery Is a Key Tool in Modern Drug Development

PLGA has become a central material for advanced drug delivery because it combines:

- Biodegradability and safety

- Flexible and tunable release profiles

- Multiple formats, from microspheres to nanoparticles and implants

- Strong regulatory and clinical experience

If you are exploring PLGA-based formulation design, nanoparticle development, or controlled-release strategies, partnering with an experienced CRO can help you move faster and reduce risk. Creative Biolabs supports PLGA-based delivery research with integrated formulation development, characterization, and optimization services, allowing you to translate your drug candidates into robust, patient-friendly products.

For Research Use Only. Not for Clinical Use.

References

References

- Horvath, D. & Basler, M. "PLGA Particles in Immunotherapy." Pharmaceutics 15, 615 (2023). https://www.mdpi.com/1999-4923/15/2/615. Distributed under Open Access license CC BY 4.0, without modification.

- Lu, Y. et al. "Properties of Poly (Lactic-co-Glycolic Acid) and Progress of Poly (Lactic-co-Glycolic Acid)-Based Biodegradable Materials in Biomedical Research." Pharmaceuticals 16, 454 (2023). https://www.mdpi.com/1424-8247/16/3/454.

- Su, Y. et al. "PLGA-based biodegradable microspheres in drug delivery: recent advances in research and application." Drug Delivery 28, 1397–1418 (2021). https://www.tandfonline.com/doi/full/10.1080/10717544.2021.1938756.

- Strus, B. & Szterk, A. "PLGA‐PEG‐PLGA Polymer: From Synthesis to Advanced Pharmaceutical Applications." Advances in Polymer Technology 2025, 8899828 (2025). https://onlinelibrary.wiley.com/doi/10.1155/adv/8899828.

- Yang, J. et al. "Recent Applications of PLGA in Drug Delivery Systems." Polymers 16, 2606 (2024). https://www.mdpi.com/2073-4360/16/18/2606. Distributed under Open Access license CC BY 4.0, without modification.