Nanofiber Delivery Strategies: A Clear and Simple Guide for Modern Drug Delivery

Nanofiber delivery strategies are quickly becoming one of the most promising tools in modern drug delivery because they offer precise control, high drug loading, and enhanced protection for sensitive molecules. Their ultra-thin structure allows medicines to be released slowly and exactly where needed, which improves stability and reduces unwanted side effects. As the market continues to embrace innovative delivery platforms, nanofibers are gaining attention across wound care, oncology, vaccines, and regenerative medicine. In this article, Creative Biolabs will explain these strategies in simple, clear terms and show how they can support next-generation therapeutic design.

What Are Nanofiber Delivery Strategies?

Nanofibers are fibers so thin that their diameter is at the nanometer scale. To put it simply, they are thousands of times thinner than a human hair. Because they are so thin, they have a very high surface area and many tiny spaces, or pores, between fibers.

Nanofiber delivery strategies use these special fibers as carriers for drugs, biologics, or other active molecules. The drug can be mixed into the fiber, coated on the surface, or placed in a special inner "core" layer. When the nanofiber mat is applied to the body, the drug moves out over time in a controlled way.

For modern drug developers, nanofiber delivery strategies provide a bridge between simple topical systems and advanced nanomedicine, combining easy fabrication with very smart release behavior.

How Nanofibers Work in Drug Delivery

Nanofibers help drug delivery in several clear and practical ways:

- High surface area: Because the fibers are so thin, a lot of surface is available for drug loading and interaction with tissues.

- Porous structure: The spaces between fibers let water and body fluids flow in, dissolve the drug, and carry it out over time.

- Flexible design: By changing the polymer, fiber diameter, and structure, scientists can tune how fast and how completely the drug is released.

- Tissue-mimicking behavior: Electrospun nanofibers can look and feel like the body's own extracellular matrix, which helps cells attach and grow.

In practice, a nanofiber mat can:

1. Hold a drug at a high loading level.

2. Protect it from light, oxygen, or enzymes.

3. Release it over hours or days, instead of in one large burst.

This combination of protection plus programmable release is what makes nanofiber delivery strategies so attractive for next-generation drug products.

Nanofiber vs Traditional Drug Delivery Systems

Below is a simple side-by-side comparison of nanofiber delivery systems with more traditional formats, such as ointments, films, or bulk hydrogels (Table 1). Although traditional systems are familiar and convenient, it can be seen that nanofibers offer several performance advantages that make them especially useful for modern therapeutic design.

Table 1 Comparison of nanofiber delivery strategies with traditional systems.

| Feature | Nanofiber Delivery Strategies | Traditional Systems (Ointments, Films, Bulk Gels) |

|---|---|---|

| Drug loading | High, can exceed 80-90% in optimized systems | Often limited, especially for hydrophobic or large molecules |

| Release control | Fine control from fast to very slow (hours–days) | Often, a fast burst or simple diffusion |

| Surface area | Very high, improves interaction with tissue | Lower surface area |

| Tissue mimicry | Can mimic the extracellular matrix | Usually does not mimic native tissue |

| Targeting options | Easy to combine with ligands or smart polymers | More difficult to integrate targeting features |

| Scalability | Growing electrospinning scale-up solutions | Established, but may lack nano-level control |

Types of Nanofibers Used in Drug Delivery

There are many types of nanofibers, but most drug delivery systems fall into a few clear groups:

Electrospun nanofibers

The most common form. They are made by electrospinning a polymer solution and can hold small molecules, proteins, or nucleic acids.

Composite nanofibers

These combine two or more materials, such as a polymer plus nanoparticles, to add extra functions like imaging or magnetic control.

Core-shell nanofibers

Here, one material forms the "core" and another forms the "shell". This design allows a two-stage release or strong protection of sensitive drugs inside the core.

Biodegradable nanofibers

Made from polymers that break down in the body, such as PLA or PCL. These are ideal for temporary implants or tissue scaffolds.

Stimuli-responsive nanofibers

These fibers change their behavior when the environment changes (pH, temperature, light, or magnetic field). They can release more drugs only when and where it is needed.

Together, these diverse nanofiber types give researchers a flexible "toolbox " for designing nanofiber delivery strategies tailored to each drug's stability, release profile, and targeting needs.

To explore how these approaches can be incorporated into broader targeted delivery programs, you can visit our Module Delivery Systems page at: https://www.creative-biolabs.com/targeted-delivery/module-delivery-systems.htm.

Electrospinning: The Most Important Method for Making Nanofibers

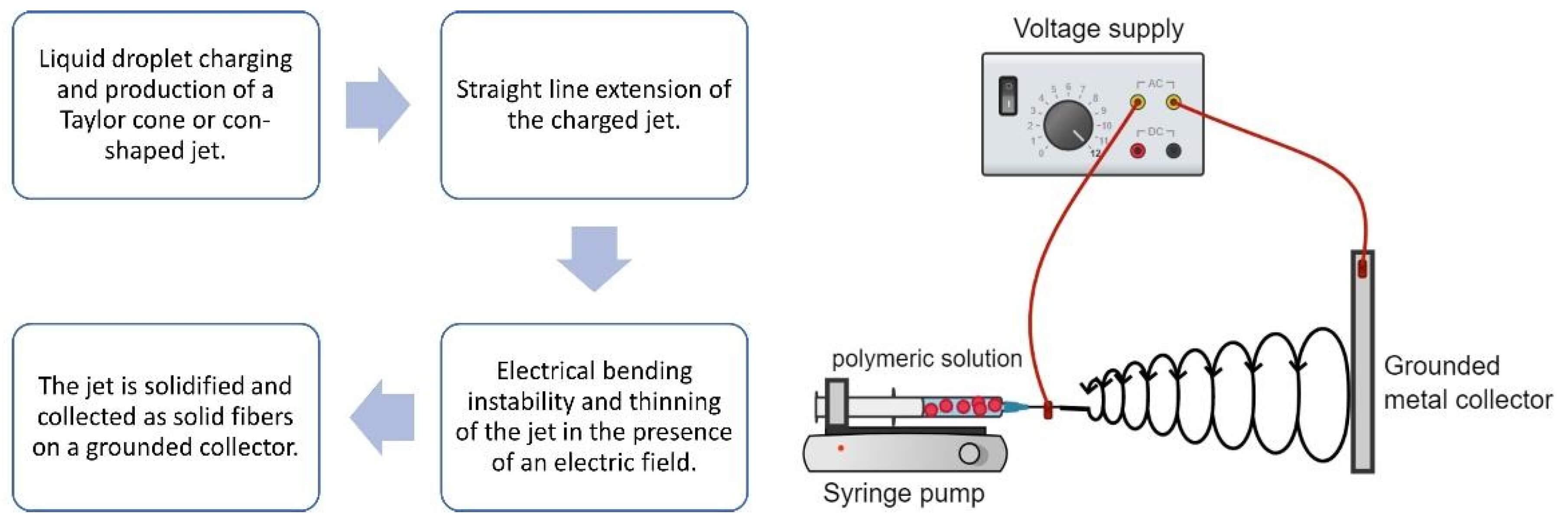

Electrospinning is the workhorse method for making nanofibers for drug delivery (Figure 1). It is powerful yet surprisingly simple:

- A polymer-drug solution is loaded into a syringe.

- A high voltage is applied between the needle tip and a collector.

- The electric field stretches the liquid into a fine jet.

- The solvent evaporates in the air, and solid nanofibers land on the collector as a nonwoven mat.

Fig.1

The electrospinning process.1

Fig.1

The electrospinning process.1

By tuning voltage, distance, flow rate, and solution properties, scientists can control:

- Fiber diameter

- Porosity

- Drug distribution (surface vs core)

- Mechanical strength

Many reviews now describe electrospun nanofibers as one of the most promising platforms for controlled and localized drug release, especially in wound care, tumor patches, and tissue engineering scaffolds.

Electrospinning turns a simple liquid into a highly engineered, nanostructured medicine delivery platform.

Real-World Applications Across Medicine & Industry

Nanofiber delivery strategies are already making a real impact in medicine and industry, offering practical solutions for targeted treatment, controlled release, and tissue-friendly healing across multiple therapeutic areas.

Oncology (Localized Chemotherapy)

Nanofiber patches can be placed close to a tumor site to slowly release chemotherapeutic drugs. This approach may reduce systemic exposure while keeping a high local concentration at the tumor region.

Wound Healing (Nanofiber Dressings)

Electrospun nanofiber dressings can:

- Keep the wound moist

- Allow gas exchange

- Deliver antibiotics, growth factors, or anti-inflammatory agents

Because the fibers mimic the natural extracellular matrix, they also help cells grow and close the wound.

Vaccines & Biologics

Nanofiber mats can stabilize proteins, peptides, and even nucleic acids, which are often sensitive to heat and enzymes. Their high loading and gentle release make them attractive for vaccine delivery and mucosal immunization.

Tissue Engineering Scaffolds

In tissue engineering, nanofibers act as scaffolds where cells can attach, spread, and form new tissue. Drug or growth factor loading turns these scaffolds into active therapeutic implants rather than passive structures.

Regenerative Medicine

In regenerative medicine, nanofiber delivery strategies can support:

- Nerve regeneration

- Bone and cartilage repair

- Skin and soft tissue reconstruction

By tuning degradation and release profiles, the scaffold can "support and then disappear" as new tissue forms.

Topical and Transdermal Delivery

Nanofiber patches placed on the skin can deliver drugs through or across the skin over time. This is valuable for pain management, hormone therapy, and local anti-inflammatory treatments.

Fig.2

Applications of polymeric nanofibers for drug delivery.2

Fig.2

Applications of polymeric nanofibers for drug delivery.2

To support teams exploring these advanced applications, Creative Biolabs also offers flexible formulation design and targeted delivery development services, which you can learn more about in our dedicated Module Delivery Systems resource: https://www.creative-biolabs.com/targeted-delivery/module-delivery-systems.htm.

Challenges in Nanofiber Drug Delivery

Despite their promise, nanofiber delivery strategies still face some practical hurdles:

- Scalability: Moving from lab-scale electrospinning to stable, industrial production lines requires careful control of process parameters and quality systems.

- Biocompatibility and safety: Polymers and additives must be safe, non-toxic, and acceptable to regulators. Long-term degradation products must also be understood.

- Batch consistency: Small changes in humidity, solution quality, or voltage can alter fiber structure and drug distribution, which can affect release profiles.

- Regulatory pathway: Many nanofiber products combine device and drug features, so they may face complex "combination product" routes for approval.

Because of these points, many organizations choose to work with specialized partners who already have experience in nanofiber design, testing, and scale-up.

Future Prospects: AI-Driven, Personalized Nanofibers

Looking forward, the field is moving towards even smarter nanofiber delivery strategies:

- AI-assisted design: Machine learning can help predict the best polymer blends, fiber diameters, and drug loading methods to meet a given release profile.

- Smart, stimuli-responsive fibers: Systems that respond to pH, temperature, light, or magnetic fields can release extra drug only when needed, which can improve safety and effectiveness.

- Personalized patches and scaffolds: In the future, patient-specific data and 3D models may guide custom nanofiber implants or patches tailored to each individual.

These trends align well with the global move toward precision medicine and patient-centered therapy.

Related Services You May Be Interested in

FAQs

What are nanofiber delivery systems?

Nanofiber delivery systems use very thin fibers, usually made by electrospinning, to carry drugs and release them slowly. Their high surface area and porous structure allow high drug loading and controlled release, which is helpful for wound care, cancer patches, and tissue engineering.

How are nanofibers made for drug delivery?

Most drug-loaded nanofibers are made by electrospinning. In this method, a polymer–drug solution is pulled into fine fibers by a strong electric field, and the solvent evaporates to leave a solid nanofiber mat that can be cut or shaped into patches, dressings, or scaffolds.

What are the main benefits of nanofiber-based drug delivery?

Key benefits include high drug loading, tunable release (from quick to very slow), protection of sensitive molecules, and the ability to mimic natural tissue. These features can improve local drug levels, reduce side effects, and support better healing in many applications.

What are the challenges in nanofiber drug delivery?

The main challenges are scaling up production, keeping batches consistent, proving long-term safety and biocompatibility, and navigating complex regulatory pathways, especially for combination products that act as both device and drug.

Which medical fields are adopting nanofiber delivery fastest?

Oncology, wound care, tissue engineering, regenerative medicine, and advanced topical or transdermal therapies are among the fastest adopters. These areas benefit most from localized, sustained, and tissue-mimicking delivery formats.

What is the future outlook for nanofiber drug delivery?

The nanofiber market is expected to more than double over the next decade, with medical and pharmaceutical uses growing especially fast. At the same time, AI-assisted design and smart, stimuli-responsive fibers will push nanofiber delivery strategies deeper into precision medicine.

Conclusion: Turn Nanofiber Delivery Strategies into Real Research Impact

Nanofiber delivery strategies offer a powerful mix of high drug loading, precise release control, and tissue-like structure. They are already reshaping wound care, cancer therapy, tissue engineering, and advanced topical systems, and their role will only grow as markets and technologies continue to expand.

If you are planning a new delivery concept, improving an existing formulation, or comparing nanofibers with other carriers, you do not have to navigate this alone.

Creative Biolabs can partner with you from early idea through preclinical validation, bringing together targeted delivery know-how, flexible module design, and deep analytical support.

Ready to explore nanofiber delivery strategies for your next project?

Reach out to Creative Biolabs today, share your goals, and let our team help you design, test, and refine a nanofiber-based solution that truly fits your science.

How Creative Biolabs Supports Nanofiber Delivery Research

At Creative Biolabs, we help researchers and developers turn nanofiber delivery strategies into real, testable solutions. While many of our projects span liposomes, polymeric particles, and other carriers, the same targeted delivery logic also extends naturally to nanofiber-based systems.

Depending on your program stage, our team can support:

- Concept and feasibility: Selecting suitable polymers, drug types, and release goals.

- Formulation and optimization: Designing nanofiber compositions and structures that match your pharmacokinetic targets.

- Targeted delivery strategy design: Combining surface ligands, responsive materials, or co-delivery approaches to improve targeting and efficacy.

- Analytical and release testing: In-vitro and ex-vivo studies to understand release profiles, stability, and tissue interaction.

You can explore our broader delivery expertise in our Module Delivery Systems section, where we explain how different carriers are combined into flexible, project-ready, targeted delivery solutions.

References

- Jiffrin, R. et al. Electrospun Nanofiber Composites for Drug Delivery: A Review on Current Progresses. Polymers 14, 3725 (2022). https://www.mdpi.com/2073-4360/14/18/3725. Distributed under Open Access license CC BY 4.0, without modification.

- Duan, X., Chen, H. & Guo, C. Polymeric Nanofibers for Drug Delivery Applications: A Recent Review. J Mater Sci: Mater Med 33, 78 (2022). https://link.springer.com/10.1007/s10856-022-06700-4. Distributed under Open Access license CC BY 4.0, without modification.