Custom Plate Oligonucleotide Synthesis Service

Introduction

Our Custom Plate Oligonucleotide Synthesis service streamlines R&D workflows via advanced solid-phase synthesis and strict quality control, delivering high-quality, sequence-specific oligonucleotides in array formats to accelerate discovery.

[Discover How We Can Help]

Custom Plate Oligonucleotide Synthesis

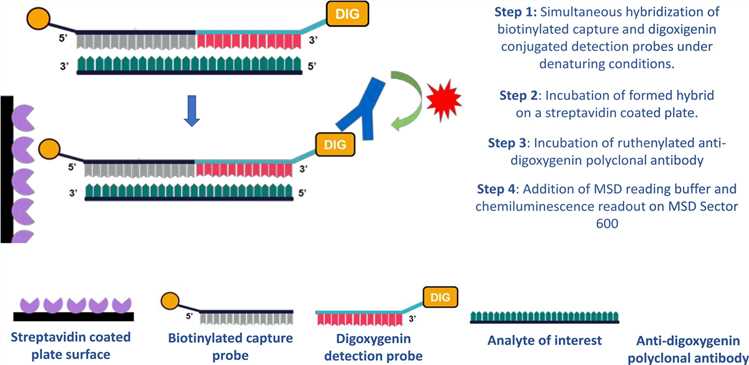

Custom Plate Oligonucleotide Synthesis, a cornerstone of modern molecular biology, creates short DNA/RNA chains directly in microplates. Developed for high-throughput, cost-effective, reproducible genetic material synthesis, it integrates automated synthesis and modifications like LNA (boosting stability/affinity). Used in gene studies and therapeutic oligonucleotide quantification (e.g., ultrasensitive POE immunoassay), these oligonucleotides are indispensable.

Fig.1 A schematic diagram of the sandwich structure for POE immunoassay and a brief description of the operation steps.1

Fig.1 A schematic diagram of the sandwich structure for POE immunoassay and a brief description of the operation steps.1

Workflow

-

Required Starting Materials

- Oligonucleotide Sequences: Detailed sequences for each oligonucleotide required, including any specific modifications or degenerate positions.

- Plate Format and Quantity: Specification of the desired microplate format (e.g., 96-well, 384-well) and the total number of plates needed.

- Purity and Concentration Requirements: Any specific purity levels and desired final concentrations or aliquoting instructions.

-

Synthesis

Custom Plate Oligonucleotide Synthesis relies on solid-phase chemical synthesis and simultaneously creates multiple distinct sequences. It starts with a nucleoside anchored to a solid support (e.g., CPG matrix) in each microplate well, followed by sequential addition of activated phosphoramidite building blocks (A/T/C/G for DNA; A/U/C/G for RNA) via automated, controlled cycles of deprotection, coupling, oxidation, and capping. This plate-based approach enables parallel synthesis of hundreds of unique sequences, boosting throughput and cutting cost per base vs. traditional methods.

-

Purification

Following synthesis, crude oligonucleotides contain various impurities, including truncated sequences, unreacted reagents, and protecting groups. Effective purification is crucial to ensure the high quality required for sensitive downstream applications. Creative Biolabs offers a range of purification options tailored to your specific needs:

- Desalting: A basic purification method that removes salts and small molecular weight impurities.

- Gel Filtration: Separates oligonucleotides based on size, effectively removing shorter, incomplete sequences.

- Reverse Phase Cartridge Purification: A more stringent method, particularly effective for removing hydrophobic impurities and often used for modified oligonucleotides.

-

Quality Control

- Capillary Electrophoresis (CE): High-resolution separation for precise purity assessment and detection of truncated sequences.

- High-Performance Liquid Chromatography (HPLC): Additional purity analysis, critical for distinguishing full-length products from closely related impurities.

- Mass Spectrometry (MS): Confirms exact molecular weight, verifying sequence and modification incorporation to ensure fidelity.

- Absorbance Measurements: Quantifies yield for accurate concentration data. These checks ensure oligonucleotides meet strict specs, boosting research confidence.

-

Estimated Timeframe

The typical timeframe for our Custom Plate Oligonucleotide Synthesis service ranges from 3 to 8 weeks, depending on the complexity of the sequences, the number and type of modifications, the total quantity of oligonucleotides, and the chosen purification methods.

What We Can Offer

High-throughput synthesis

Simultaneous synthesis of multiple oligonucleotides in a single microplate (e.g., 96/384-well), meeting large-scale experiment demands, boosting efficiency, and reducing individual synthesis costs.

Strong specificity

Artificially designed to target nucleic acid sequences, binding specifically via base pairing, ensuring high specificity in gene testing, gene silencing, etc.

Convenient detection

Compatible with microplate technology for diverse detections (e.g., sandwich hybridization to fix complexes, enzyme-probe conjugation for target detection), with simple, automatable operations.

Wide application

Serves as primers (DNA replication, PCR, sequencing), molecular probes (in situ hybridization, gene knockdown), and in antisense therapy—applied across biomedical research and drug development.

High stability

Reasonably designed/modified plate oligonucleotides (e.g., thiophosphate DNA with modified phosphate skeletons) resist nuclease degradation; array plates have a shelf life of over 5 years under proper storage.

[Get a Quote Today and see how our expertise can elevate your research]

Customer Reviews

FAQs

What types of modifications can be incorporated into plate oligonucleotides?

We offer diverse chemical modifications to enhance stability, affinity, or add functionalities: backbone modifications (e.g., phosphorothioate for nuclease resistance), sugar modifications (2'-O-methyl, LNA for better binding, etc.), and reporter/ligand conjugations (e.g., biotin, fluorophores, GalNAc). Contact our team to discuss your specific modifications.

How does plate oligonucleotide synthesis improve my high-throughput screening efforts?

Plate oligonucleotide synthesis enhances high-throughput capabilities by producing hundreds of unique sequences simultaneously in one run. It cuts synthesis time and per-oligonucleotide cost, enabling rapid generation of large libraries for gene silencing screens, diagnostic arrays, or PCR primer sets. The array format simplifies downstream automation.

What quality control measures does Creative Biolabs implement to ensure the accuracy of my custom oligonucleotides?

We implement rigorous multi-stage quality control: each oligonucleotide batch undergoes CE and HPLC for purity, MS for sequence and modification verification, and absorbance measurements for yield accuracy. These checks ensure top-quality oligonucleotides that meet your specifications.

Can I receive my oligonucleotides in a ready-to-use format, such as dissolved or aliquoted?

Beyond standard dried oligonucleotides in microtubes, we offer convenient formats: aliquoted oligos, dissolved ones at specified concentrations (e.g., 100 μM) for immediate use, and dried/dissolved equimolar oligos in 96-well plates for high-throughput needs.

How does Creative Biolabs' Custom Plate Oligonucleotide Synthesis compare to traditional synthesis methods in terms of cost and turnaround time?

Our plate-based synthesis offers cost and turnaround advantages, especially for multi-sequence projects. Parallel synthesis of numerous oligonucleotides reduces the cost per base vs. single-column methods, while automated high-throughput processing ensures faster delivery.

Contact Our Team to Discuss Your Project today!

Reference

- Thayer, Mai B., et al. "POE Immunoassay: Plate-based oligonucleotide electro-chemiluminescent immunoassay for the quantification of nucleic acids in biological matrices." Scientific Reports 10.1 (2020): 10425. DOI: 10.1038/s41598-020-66829-6. Distributed under Open Access license CC BY 4.0, without modification.