Recent pharmaceutical advancements have seen a significant shift towards the incorporation of nanostructured elements, particularly in the realm of precise drug targeting. Nanodrugs include a range of pharmaceutical formulations, including nanoemulsion, nanocrystals, micelles, dendrimers, liposomes and polymer nanoparticles. Liposomes, being the most researched nanoparticles, are efficient carriers involving multiple preparation steps. The complexity of their structure necessitates enhanced process control and monitoring of quality attributes.

The manufacturing of liposomes encompasses a multitude of steps, where complexity in structure necessitates stringent process control and quality attribute surveillance post-production. Liposomes, as highly researched nanoparticles, require careful quality control (QC) to ensure attributes like particle size, size distribution (indexed by PDI), surface charge (ascertained by zeta potential), morphology, lamellarity, phase behavior, drug release kinetics, and encapsulation efficiency meet the required standards. This meticulous evaluation guarantees optimum in vitro and in vivo performance.

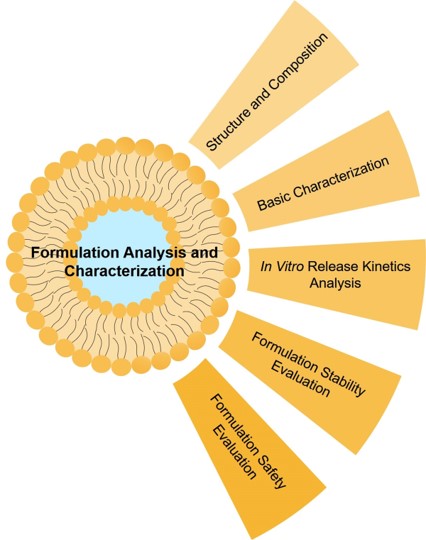

Fig.1 Formulation analysis and characterization.

Fig.1 Formulation analysis and characterization.

The following table summarizes the main analytical techniques used for liposome characterization.

| Characteristics | Techniques |

|---|---|

| Morphology | Microscope technology: Scanning and transmission electron microscopy (SEM/TEM), cryogenic-TEM (Cryo-TEM), and atomic force microscopy (AFM) |

| Particle size and size distribution |

Microscope technology: SEM/TEM, Cryo-TEM, and AFM Dynamic light scattering (DLS) |

| Lamellarity | Cryo-TEM and 31P-NMR |

| Phase behavior |

X-ray diffraction (XRD) Differential scanning calorimetry (DSC) Thermogravimetric analysis (TGA) Fourier transform infrared spectroscopy (FTIR) |

| Surface charge/Zeta potential |

Electrophoretic mobility DLS Phase analysis light scattering (PALS) |

| Encapsulation efficiency/ Drug loading | Drug content analysis following the separation of free drugs using ultrafiltration, dialysis and size exclusion chromatography, with subsequent quantification employing chromatographic or spectrophotometric techniques. |

| In vitro drug release |

Stable nanoparticle formulations should maintain their integrity during in vitro storage and in vivo circulation to ensure that the encapsulated drugs are not released before reaching their target sites. Separate (SS) Dialysis membrane (DM) Continuous flow (CF) |

|

Stability -Physical stability -Chemical stability |

For lipid-based drug delivery systems to be effective, they must exhibit both physical and chemical stability. This means that the nanoparticles should preserve a consistent size distribution and a stable drug encapsulation level, while the lipids and drugs must remain intact during storage. |

The slow progress in the mass production of liposomes is often attributed to the challenges in addressing technical and quality control issues. As a leading professional liposome development company, Creative Biolabs is dedicated to overcoming these hurdles. Our comprehensive quality control and testing services are tailored to ensure the highest quality standards for both our proprietary and client-provided liposomes. We specialize in maintaining the integrity and efficacy of your formulations and invite you to contact us today to discuss how we can support your specific needs.

For Research Use Only. Not For Clinical Use

For Research Use Only. Not For Clinical UseSupports

Online Inquiry