-

Solutions

- Live Attenuated & Killed Vaccine Design

- Subunit Vaccine Design

- Hapten Conjugate Vaccine Design

- Totally Synthetic Vaccine Design

- DNA & RNA Vaccine Design

- Viral Vector Vaccine Design

- Bacterial Vector Vaccine Design

- Virus-Like Particle based Vaccine Design

- Cell based Vaccine Design

- Plant based Vaccine Design

- Bacterial Vaccine Design

- Viral Vaccine Design

- Fungal Vaccine Design

- Parasitic Vaccine Design

- HBV Vaccine Design

- HPV Vaccine Design

- Diabetes Mellitus Vaccine Design

- Autoimmune Disease related Vaccine Design

- Neurodegenerative Disease related Vaccine Design

-

Allergic Disease related Vaccine Design

- Target-AgTM Platform

- Peanut Allergy Vaccine Design

- Plant Pollens Allergy Vaccine Design

- Cow's Milk Allergy Vaccine Design

- Egg Allergy Vaccine Design

- Seafood Allergy Vaccine Design

- Fruit Allergy Vaccine Design

- Bee Venom Allergy Vaccine Design

- Latex Allergy Vaccine Design

- Furry Animals Allergy Vaccine Design

- Tree Nut Allergy Vaccine Design

- House Dust Mite Induced Allergic Asthma Vaccine Design

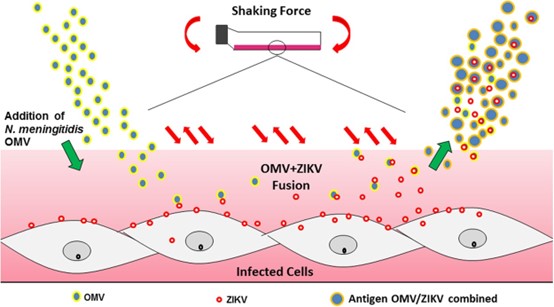

- Exosome-based Vaccine Design

- Universal Vaccine Design

-

Services

- Vaccine Design

-

Vaccine Formulation Development

- Formulation Optimization

- Delivery System Optimization

- Adjuvant Optimization

- Adjuvant Selection

- PRR Ligand Scanning

- Custom Adjuvant Synthesis

- Mineral Salt Adjuvant related Optimization

- Oil Adjuvant related Optimization

- Saponin related Optimization

- Lipopolysaccharide related Optimization

- CpG related Optimization

- Bacteria-derived Adjuvant Optimization

- Adjuvant Emulsion Optimization

- Innate Immune Stimulator Design

- RNA-based Adjuvant Optimization

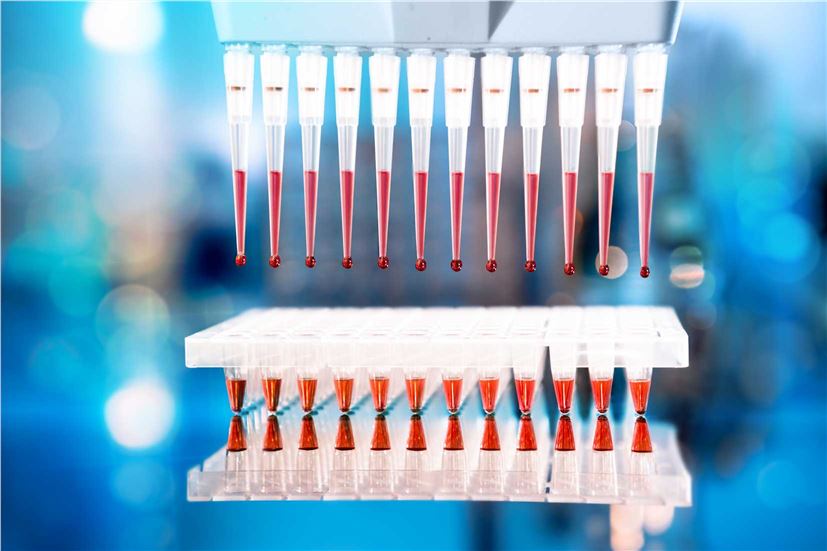

- Vaccine Analytical Development & Qualification

-

Vaccine GMP Manufacturing

- Expression System Evaluation

- Bacterial Expression System for Vaccine Production

- Yeast Expression System for Vaccine Production

- Baculovirus-Insect Expression System for Vaccine Production

- Mammalian Cell Expression System for Vaccine Production

- Plant Expression System for Vaccine Production

- Cell-free Expression System for Vaccine Production

- Small-Scale Process Development

- Scale-Up Development

- Vaccine GMP Production

- Serum-Free Suspension Culture

- GMP-grade Antigen Production

- Expression System Evaluation

-

Cancer Vaccines

-

Cancer Vaccine Development

- Cutaneous Cancer related Vaccine Development

- Genitourinary Cancer related Vaccine Development

- Gynecologic Cancer related Vaccine Development

- Gastrointestinal Cancer related Vaccine Development

- Breast Cancer related Vaccine Development

- Lung Cancer related Vaccine Development

- Head and Neck Cancer related Vaccine Development

- Blood Cancer related Vaccine Development

- Brain Tumor related Vaccine Development

- Sarcomas related Vaccine Development

- Pediatric Cancer related Vaccine Development

- Neuroendocrine Tumor related Vaccine Development

- Thyroid Cancer related Vaccine Development

-

Cancer Vaccine Type

- Neoantigen Cancer Vaccine Development

- Tumor Cell Vaccine Development

- Dendritic Cell Vaccine Development

- Antigen Vaccine Development

- Anti-Idiotype Vaccine Development

- DNA based Cancer Vaccine Development

- mRNA based Cancer Vaccine Development

- Vector based Vaccine Development

- Fully Synthetic Carbohydrate based Cancer Vaccine Development

- BCG Vaccine Development

- Ty21 based Vaccine Development

- Exosome based Therapeutic Cancer Vaccine Development

- Ag-Fc Fusion Protein based Vaccine Development

- Biomaterial-based Implantable Cancer Vaccine Development

- Cytomegalovirus based Cancer Immunotherapy Development

- Immunological Checkpoint Therapy Development

- Immunoplacental Therapy Development

- Cancer Vaccine Technology

-

Cancer Vaccine Development

- Products

-

Supports

- FAQs

- Literature Center

- Download Resources

- Podcast

-

Scientific Frontier

- Murine vs. Human Norovirus Models in Vaccine Research

- Norovirus Immune Evasion and the Challenge of Durable Vaccine Protection

- Norovirus Vaccine Development – Where Are We Now in 2025

- Virus-Like Particle Vaccines for Norovirus – A Promising Immunological Strategy

- Why Rotavirus Vaccines Don't Protect Against Norovirus

- Understanding the Molecular Mechanisms of Three RSV Vaccine Construction Strategies

- Respiratory Syncytial Virus F Protein in Next-Generation Vaccine Design

- RSV Infection Life Cycle and Vaccine Target Discovery

- The Translational Value of BRSV Models in Human RSV Vaccine

- Deciphering the Molecular Mechanisms of Respiratory Syncytial Virus Infection

- Rabies Virus Vaccine:Revealing Potential Vaccine Targets

- Biological Research on mRNA Rabies Vaccines

- Designing mRNA Ebola Vaccines: Delivery Systems and Immunogenicity Analysis

- Ebola Virus Glycoprotein: Structure, Entry Mechanism, and Therapeutic Implications

- Ebola Virus Replication Cycle: Host Factors, RdRp Kinetics, and Vaccine Targets

- The Molecular Architecture of HPV: Decoding the L1 Capsid Protein

-

Featured Project Solutions

- Fungal Vaccine Design

- Viral Vaccine Development Solution

- Parasitic Vaccine Solution

- HBV Vaccine Solution

- HPV Vaccine Solution

- Diabetes Mellitus Vaccine Solution

- Autoimmune Disease related Vaccine Solution

- Neurodegenerative Disease related Vaccine Solution

- Allergic Disease related Vaccine Solution

- Exosome-based Vaccine Solution

- Universal Vaccine Solution

- Monkeypox Virus (MPXV) Vaccine Solution

- Vaccine Design Solution

- Vaccine Formulation Development Solution

- Vaccine Analytical Development & Qualification Solution

- Vaccine GMP Manufacturing Solution

- Cancer Vaccine Development Solution

- Featured Cancer Vaccine Type

- Featured Cancer Vaccine Technology

- Bacterial Vaccines Solution

- Subunit Vaccine Solution

- Live Attenuated and Killed Vaccine Solution

- Bacterial Vector Vaccine Solution

- Cell based Vaccine Solution

- DNA and RNA Vaccine Solution

- Hapten Conjugate Vaccine Solution

- Plant based Vaccine Solution

- Totally Synthetic Vaccine Solution

- Viral Vector Vaccine Solutions

- Virus-Like Particle based Vaccine Solution

- Company