Creative Biolabs provides an effective and high-quality immunoadhesin production service to accelerate worldwide research and development, so that addressing issues in obtaining high-quality immunoadhesins for research or therapeutic development.

Immunoadhesins have great potential across fundamental research, disease diagnostics, and treatment development by combining the binding specificity of an antibody's variable region with the effector capabilities of an immunoglobulin's constant region. Historically generated in mammalian cell culture systems such as CHO cells, which provide the benefit of human-like glycosylation essential for function, this approach may be time-consuming and expensive. A possibly scalable and reasonably affordable approach is plant-based expression systems. Therefore, speeding research and development depends on the development of effective and high-quality immunoadhesin manufacturing techniques, which guarantee more reasonably priced access to these important proteins for both research and therapeutic uses.

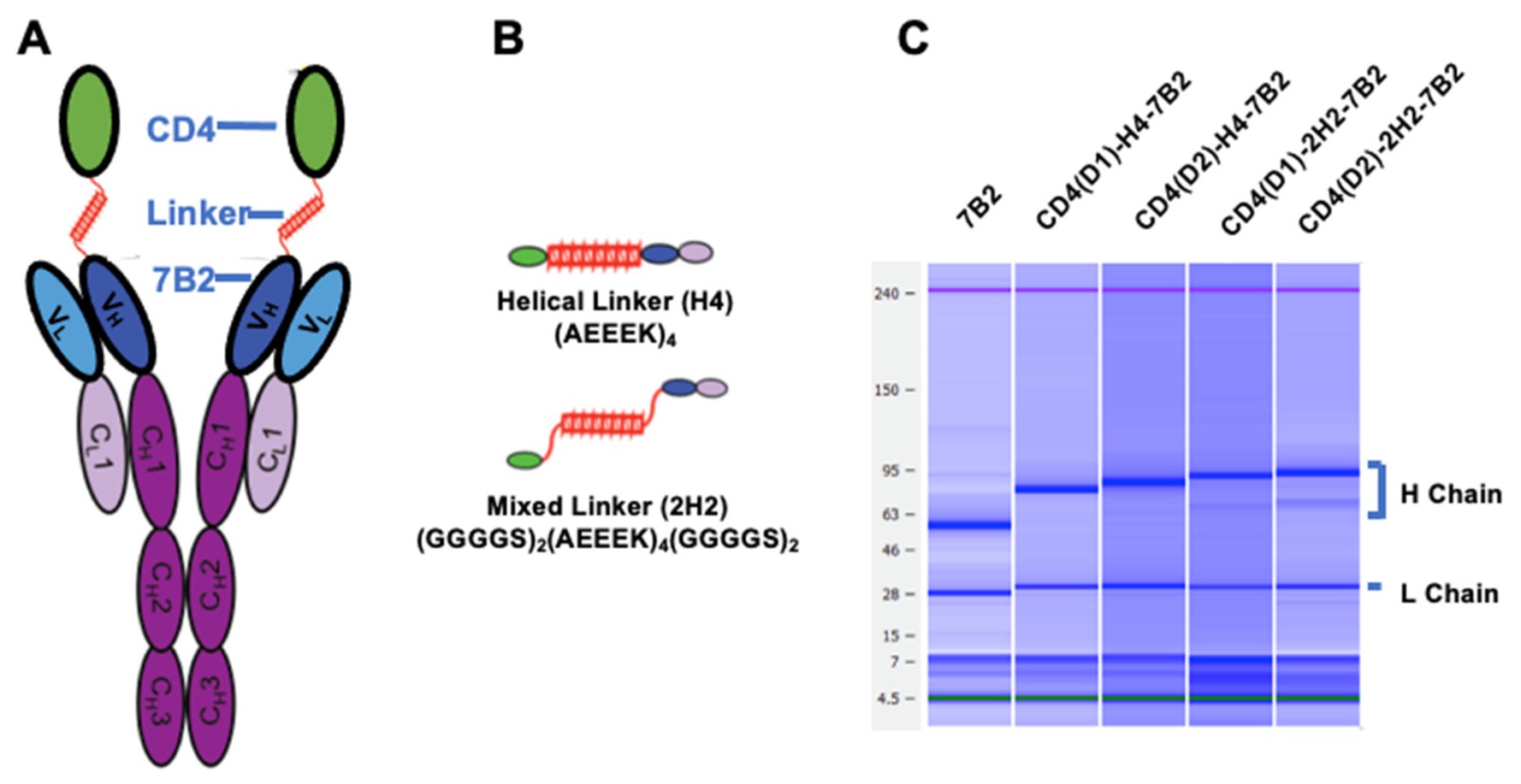

Fig.1 Design and generation of an Ig-adhesins.1

Fig.1 Design and generation of an Ig-adhesins.1

Creative Biolabs offers an efficient and high-quality immunoadhesin production service to empower your research and therapeutic development. Our advanced platforms enable the rapid generation of high-quality immunoadhesins, innovative molecules engineered to target pathogens with exceptional specificity. By fusing the binding domains of human receptors with the potent effector regions of antibodies, these immunoadhesins act as molecular decoys, effectively neutralizing viruses and bacterial toxins by preventing their interaction with host cells. At Creative Biolabs, we provide the capacity for large-scale, reliable production, ensuring a consistent supply of these crucial tools to advance your efforts in combating infectious diseases.

Conduct collaborative discussions to establish research objectives, identify the pathogenic target, and define structural parameters, production volumes, and quality metrics for the immunoadhesin construct.

Engineer the target immunoadhesin using state-of-the-art computational design tools and modular protein assembly methodologies to achieve desired binding and functional properties.

Select and iteratively refine microbial or mammalian host systems to enhance recombinant protein yield while maintaining structural fidelity and biological activity.

Execute controlled, large-scale fermentation or cell culture processes, followed by multi-step chromatographic purification to isolate the immunoadhesin with defined purity thresholds.

Employ orthogonal characterization techniques to verify physicochemical attributes, functional potency, and batch-to-batch consistency.

Supply lyophilized or formulated material accompanied by certified documentation, with provision for extended methodological guidance and troubleshooting support.

A high yield, adequate protein folding, and suitable post-translational modifications—especially glycosylation, which may dramatically affect immunoadhesin activity and immunogenicity—all depend on the host cell choice. Common expression systems include:

We need customers to provide the information listed below to start the project:

Our optimized purification process ensures that you receive immunoadhesins of the highest purity.

We tailor our service to meet your specific project requirements, including expression system selection and purification strategies.

We employ efficient workflows to deliver your immunoadhesins in a timely manner.

We offer production scales to support your research needs, from small-scale to large-scale production.

Q1: What types of immunoadhesins can you produce?

A1: We can produce a wide range of immunoadhesins, including those with various Fc regions (e.g., IgG1, IgG2, IgG4) and different linker designs.

Q2: What expression systems do you offer?

A2: We offer a variety of expression systems, including mammalian cell culture and other suitable systems. The optimal system is selected based on your specific project needs. Inquire now to find the best solution for your project.

Q3: What quality control measures do you have in place?

A3: We employ rigorous quality control testing, including SDS-PAGE, Western blot, ELISA, and functional assays, to ensure the purity and activity of our immunoadhesins. Reach out to our team for detailed quality control protocols

Q4: How do your prices compare to other providers?

A4: Our pricing is competitive, and we offer customized solutions to fit your budget. Request a quote today to learn more about our pricing options.

For more information about our efficient and high-quality immunoadhesin production service and how we can assist your project, please contact us directly.

Reference

For any technical issues or product/service related questions, please leave your information below. Our team will contact you soon.

All products and services are For Research Use Only and CANNOT be used in the treatment or diagnosis of disease.

NEWSLETTER

NEWSLETTER

The latest newsletter to introduce the latest breaking information, our site updates, field and other scientific news, important events, and insights from industry leaders

LEARN MORE NEWSLETTER NEW SOLUTION

NEW SOLUTION

CellRapeutics™ In Vivo Cell Engineering: One-stop in vivo T/B/NK cell and macrophage engineering services covering vectors construction to function verification.

LEARN MORE SOLUTION NOVEL TECHNOLOGY

NOVEL TECHNOLOGY

Silence™ CAR-T Cell: A novel platform to enhance CAR-T cell immunotherapy by combining RNAi technology to suppress genes that may impede CAR functionality.

LEARN MORE NOVEL TECHNOLOGY NEW SOLUTION

NEW SOLUTION

Canine CAR-T Therapy Development: From early target discovery, CAR design and construction, cell culture, and transfection, to in vitro and in vivo function validation.

LEARN MORE SOLUTION