Glyco-engineered Plant-based Expression System

Since it is well-known that the attachment of sugar residues efficiently affects protein homogeneity and functionality, glycosylation is one of the most addressed post-translational modifications in all eukaryotes. Due to a restricted number of glycan processing enzymes and the absence of nucleotide sugars, plants produce a relatively simple repertoire of different glycan structures. Therefore, plants are very well-suited for the production of homogenous N- and O-glycans and are increasingly used for the production of glycoproteins with desired glycans.

With rich experience in gene manipulation, Creative Biolabs has developed several efficient Nicotiana benthamiana-based expression systems for glycoengineering by precision genome editing. The glycoproteins produced by our expression systems can be developed to biopharmaceuticals with improved therapeutic potential.

Expression Systems for Glycosylation

Most of pharmaceutically relevant proteins are glycosylated, and their sugar moieties have a significant impact on their folding, assembly, solubility, serum and shelf half-life, and functionality. Thus, one approach to enhance the potency, safety, and stability of therapeutic proteins is glycoengineering, altering protein-associated carbohydrates to achieve the desirable protein properties. The challenge is to develop efficient expression systems that can consistently produce glycoproteins with homogeneous glycans on demand. The availability of such expression systems will lead to elucidating the contribution of sugar moieties for various biological functions and developing novel biologics with tailor-made glycosylation. Much effort has been made into engineering various expression systems to control glycosylation and to generate molecules with targeted sugar profiles. Nevertheless, engineering of N- and O-linked glycans on well-established expression systems remains challenging. On the one hand, most bacteria almost lack such glycan formations, and generally exhibit fundamental differences in their glycosylation abilities. On the other hand, glycosylation in mammalian cells is complex, and thus hard to control.

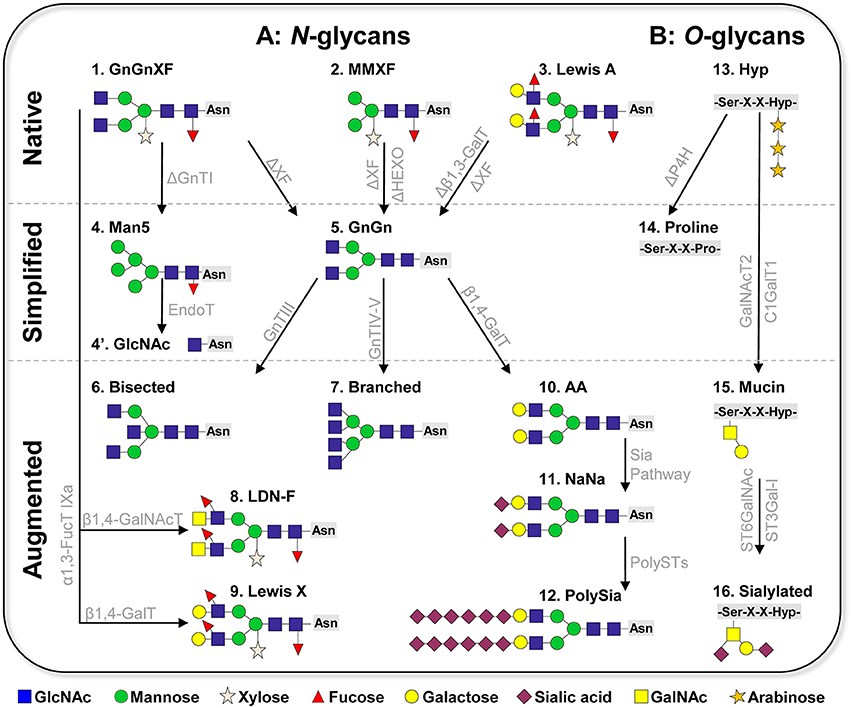

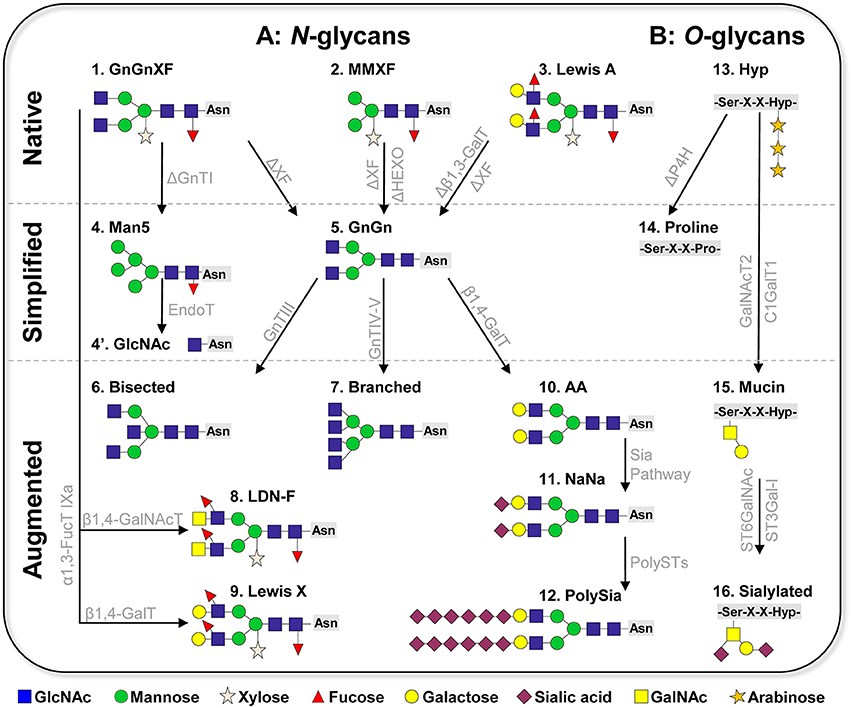

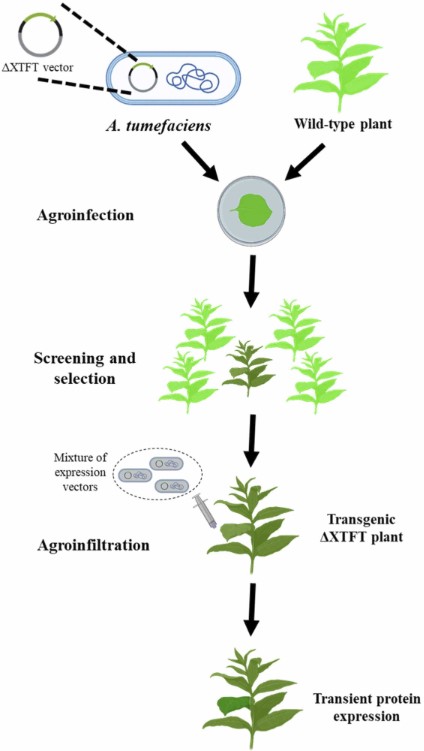

Fig.1 Schematic presentation of plant-based glycan engineering.1, 3

Fig.1 Schematic presentation of plant-based glycan engineering.1, 3

Advantages of Plant-based Expression System

Compared to mammal cells, plant cells have a drastically limited repertoire of glycoenzymes located to Golgi, and give rise to only two dominant glycan structures, GnGnXF and MMXF. As a result, unlike derived proteins derived from CHO cells that carry a mixture of several N-glycans, plant proteins usually bear a single dominant N-glycan structure. Concerns are raised that biologic proteins produced in plants might trigger immune responses due to the production of plant-glycan-specific antibodies. Paradoxically, it seems that the limited glycosylation capacity of plant cells is an advantage for specific glycan manipulations. Moreover, plant-based biomanufacturing is a relatively economic approach, with estimated a >50% reduction of capital investment and cost of goods compared to mammalian cell expression systems. N. benthamiana is currently considered the most appropriate host for biomanufacturing. Advantages of N. benthamiana include: 1) high production speed and scalability; 2) availability of genetic manipulation; 3) amenability to new plant breeding techniques, such as clustered regularly interspaced short palindromic repeats (CRISPR) gene editing; and 4) safety, which minimizes the possibility of contamination of the food supply with industrial designated products. A series of successes have achieved in N. benthamiana expression system in producing various defined human N-glycan structures, including α1,6 fucosylated, bisected, and tetra-antennary and bigalactosylated complex N-glycoforms.

Glyco-engineered Plant-based Expression System at Creative Biolabs

The common approach for plant glycoengineering is to first eliminate nonhuman sugars, and consequently generate human glycoforms by introducing mammalian enzymes. A N. benthamiana line called ΔXF has been created by suppressing the expression of two plant glycoenzymes, leading to removing plant-specific N-glycans. This strategy not only eliminates the concern for the immunogenicity of plant-specific N-glycans, but also demonstrates the plasticity of plants in tolerating the genetic manipulation of their native glycosylation pathway.

At Creative Biolabs, to extend this biosynthetic capacity, great efforts have been taken to explore efficient glyco-engineered N. benthamiana-based expression systems to meet the demands of different glycans, including standard plant N-glycans, afucosated N-glycans and humanized N-glycans, without altering the amino acid sequence of the target protein.

Highlights

-

Consistently produce glycoproteins with homogeneous glycans on demand.

-

High production speed, scalability and improved safety.

-

Overcoming issues in mammalian expression systems.

-

Flexible glycosylation controls.

Creative Biolabs offers turn-key or ala carte services customized to our client’s needs. Please contact us for more information and a detailed quote.

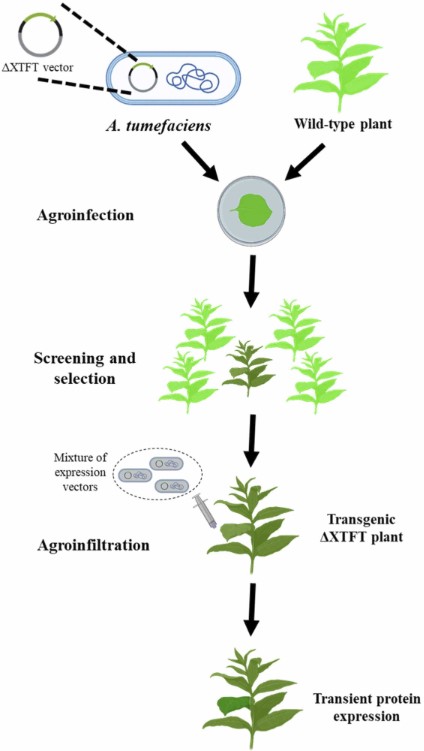

Published data

Transgenic plants are used as hosts to heterologously express and produce a variety of multifunctional therapeutic proteins. The N-glycans they produce have a higher degree of uniformity than those produced by mammalian systems. Currently, many plants are used as hosts for large-scale protein production, such as Lemna minor, N. benthamiana, N. tabacum suspension BY-2 cells, etc., which are the best choices for industrial production of recombinant proteins. Plant genetic engineering is usually carried out through Agrobacterium-mediated transformation, followed by the construction of gene knockout plant models through RNA interference and CRISPR/Cas9 technology, and then the introduction of mammalian biosynthetic genes, so that glycoengineered plants can express and produce humanized N-glycoproteins. Plant systems can synthesize various glycan structures, and their genes are easily manipulated. Therefore, they are an important way to construct target glycoproteins, which helps researchers increase their understanding and research on the functions and effects of glycosylated proteins.

Fig.2 Glycoprotein expression in plant systems.2, 3

Fig.2 Glycoprotein expression in plant systems.2, 3

FAQs

Q1: How does glyco-engineered in plant-based expression systems affect protein functionality compared to traditional expression systems?

A1: Glycoengineering allows for the production of proteins with custom glycan structures that can improve protein stability, bioactivity, and immunogenicity compared to proteins produced in traditional systems.

Q2: What are the advantages of plant-based glycoengineering expression systems over mammalian cells?

A2: Compared with mammalian cells, plant cells have a more limited combination of glycosylases and produce simpler glycosyl structures, which facilitates the manipulation of specific glycosyls. N. benthamiana is currently considered one of the most suitable hosts for biomanufacturing, with advantages such as high production speed and scalability.

Q3: How do you ensure homogeneous glycosylated proteins in plant expression systems?

A3: We have developed an efficient expression system for N. benthamiana through precise gene editing technology to achieve glycoengineering. By regulating glycosylase activity and introducing mammalian enzymes, we produce homogeneous glycosylated proteins, thereby improving their therapeutic potential.

Customer Review

Producing Consistent Glycoprotein Products

"The N. benthamiana expression system developed by Creative Biolabs has completely exceeded our expectations. The glycosylated proteins produced by this system had highly consistent N-glycosylation, which greatly improved the uniformity and functionality of our biological products."

Promoting Large-scale Production of Glycoproteins

"We are very grateful to Creative Biolabs for its excellent technology in gene editing and glycosylation control. They successfully adjusted the plant glycosylation pathway through advanced technologies such as CRISPR, helping us obtain glycoproteins that were previously only available in mammalian cells, allowing us to quickly respond to market needs and produce high-quality glycoproteins on a large scale."

References

-

Montero-Morales, Laura, and Herta Steinkellner. "Advanced plant-based glycan engineering." Frontiers in Bioengineering and Biotechnology 6 (2018): 81.

-

Kao, Mu-Rong, Rebecka Karmarkar Saldivar, and Yves SY Hsieh. "Production of therapeutic glycoproteins in glycoengineered plant: old farm for new crops." Current Opinion in Biotechnology 87 (2024): 103145.

-

Distributed under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Schematic presentation of plant-based glycan engineering.1, 3

Fig.1 Schematic presentation of plant-based glycan engineering.1, 3

Fig.2 Glycoprotein expression in plant systems.2, 3

Fig.2 Glycoprotein expression in plant systems.2, 3