In-process Chemical Composition Analysis Services

Precision Meets Excellence in Biomass Process Liquid Composition Analysis

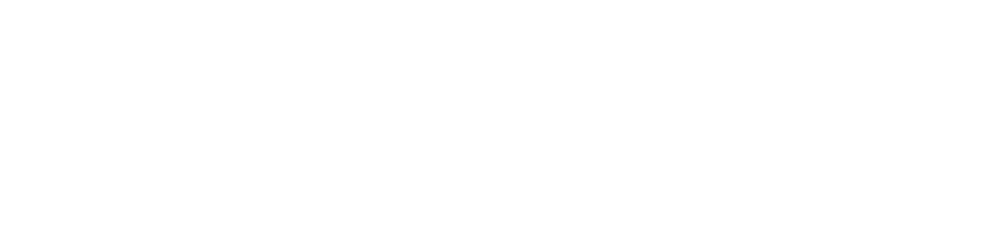

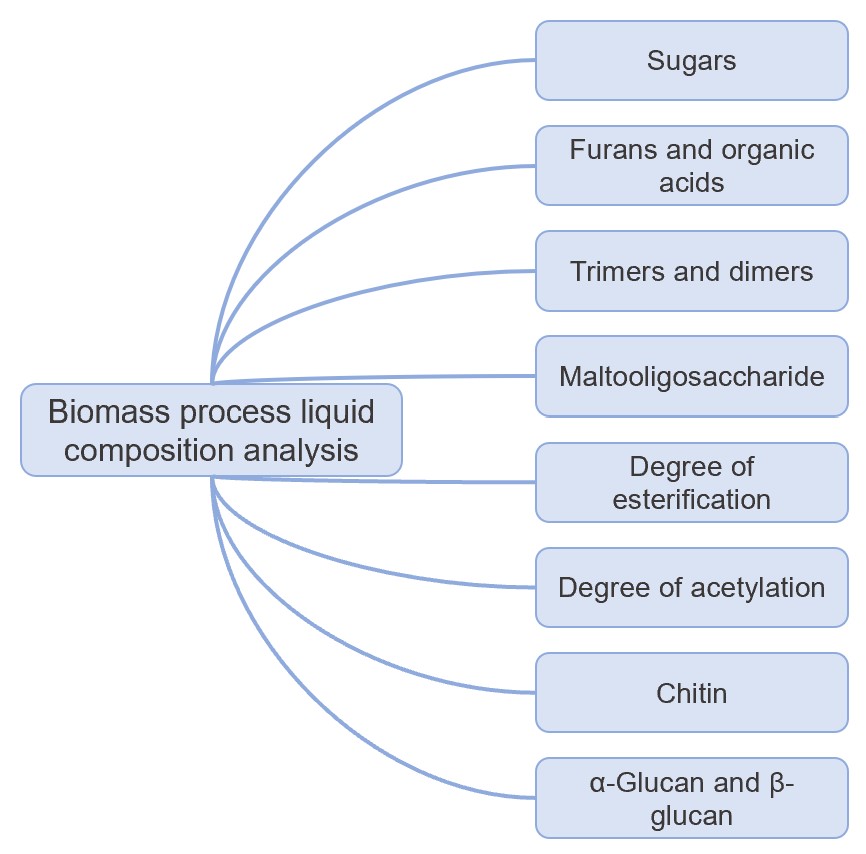

Biomass is converted into various types of products through a variety of processes. In order to gain a deeper understanding of biomass conversion, it is important to analyze the qualitative and quantitative properties of the individual substances in the conversion process. At Creative Biolabs, we provide comprehensive biomass process liquid composition analysis services according to our extensive experience in Biomass Analysis. We combine a variety of analytical techniques to detect compositional changes during biomass processing.

Our biomass process liquid analysis services apply to a wide range of samples such as Lignocellulose, Seaweed, etc., meeting the needs of various industries such as biomass conversion and biofuel production. We offer a combination of analysis services according to a variety of methods depending on the client's research objectives and sample types.

-

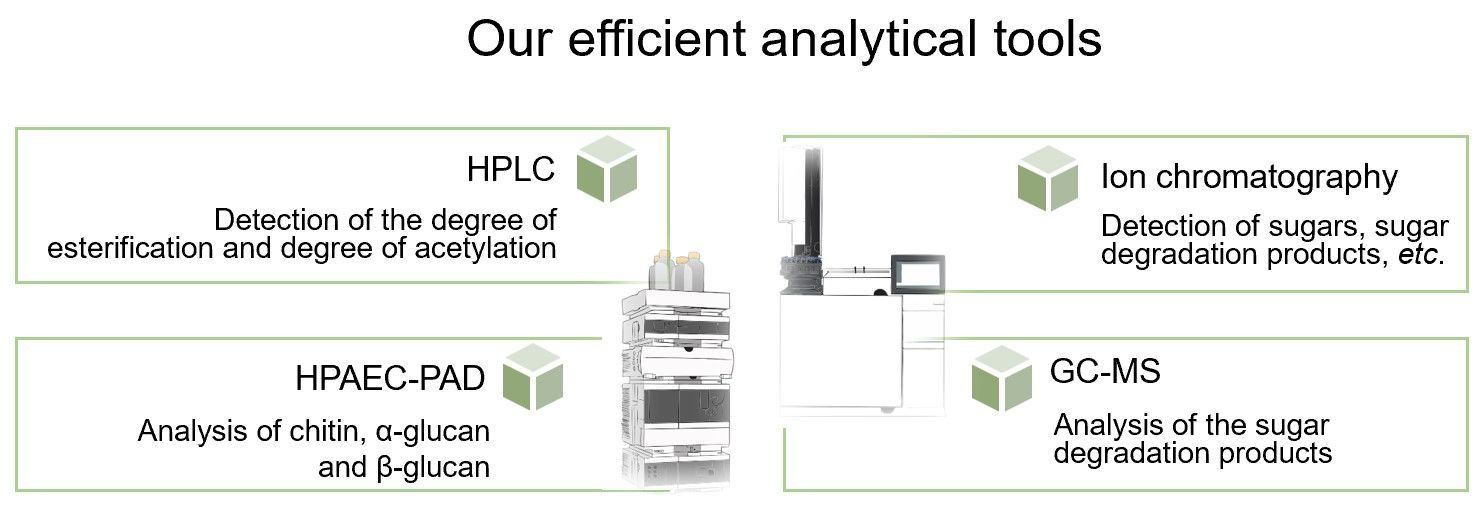

Ion chromatography

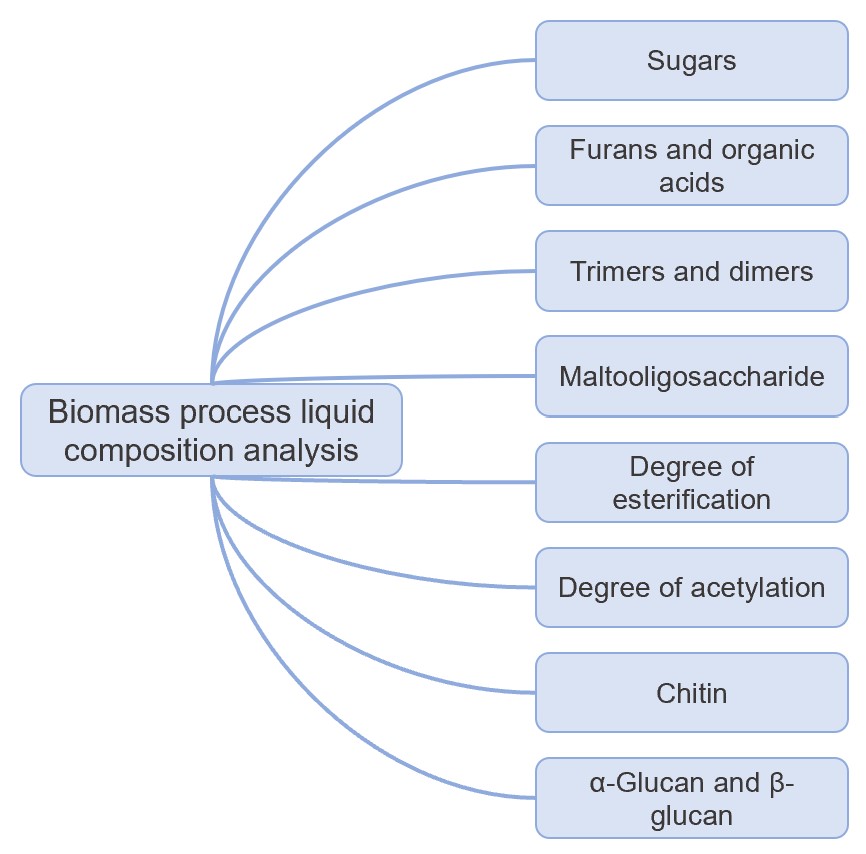

Based on its advantages in analytical speed, specificity, and sensitivity, we use ion chromatography to detect sugars, sugar degradation products, maltooligosaccharides, etc., in biomass process liquid.

-

Gas chromatography-mass spectrometry (GC-MS)

It is sensitive and is an excellent technique for component identification in complex mixtures. We analyze the sugar degradation products (furans and organic acids) in biomass process liquid by GC-MS.

-

High-performance liquid chromatography (HPLC)

We use HPLC to analyze the degree of esterification and acetylation in samples with accurate and reliable results.

-

High-performance anion-exchange chromatography with pulsed amperometric detection (HPAEC-PAD)

We use HPAEC-PAD to detect chitin, α-Glucan, and β-Glucan in individual samples. HPAEC-PAD is a reliable and sensitive analytical tool, and we have optimized its analytical process.

At Creative Biolabs, in addition to comprehensive biomass process liquid analysis, we offer the following individual analytical solutions.

Features of Biomass Process Liquid Analysis Services

-

Expertise and experience: We have professionals who specialize in biomass process liquid analysis. They are experienced and have a good understanding of the analysis of individual components, degree of acetylation, etc.

-

Comprehensive analysis: We use a variety of analytical techniques to comprehensively analyze the various parameters in biomass process liquid.

-

Quality Assurance: We observe strict quality control procedures throughout the analytical process and follow standardized methods to ensure the accuracy and reproducibility of the results.

Creative Biolabs provides custom biomass process liquid analysis services according to our client's research needs. We provide not only accurate results but also excellent technical guidance for subsequent studies. Please feel free to contact us for more information or to let us know your needs if you are interested in our biomass process liquid analysis services.

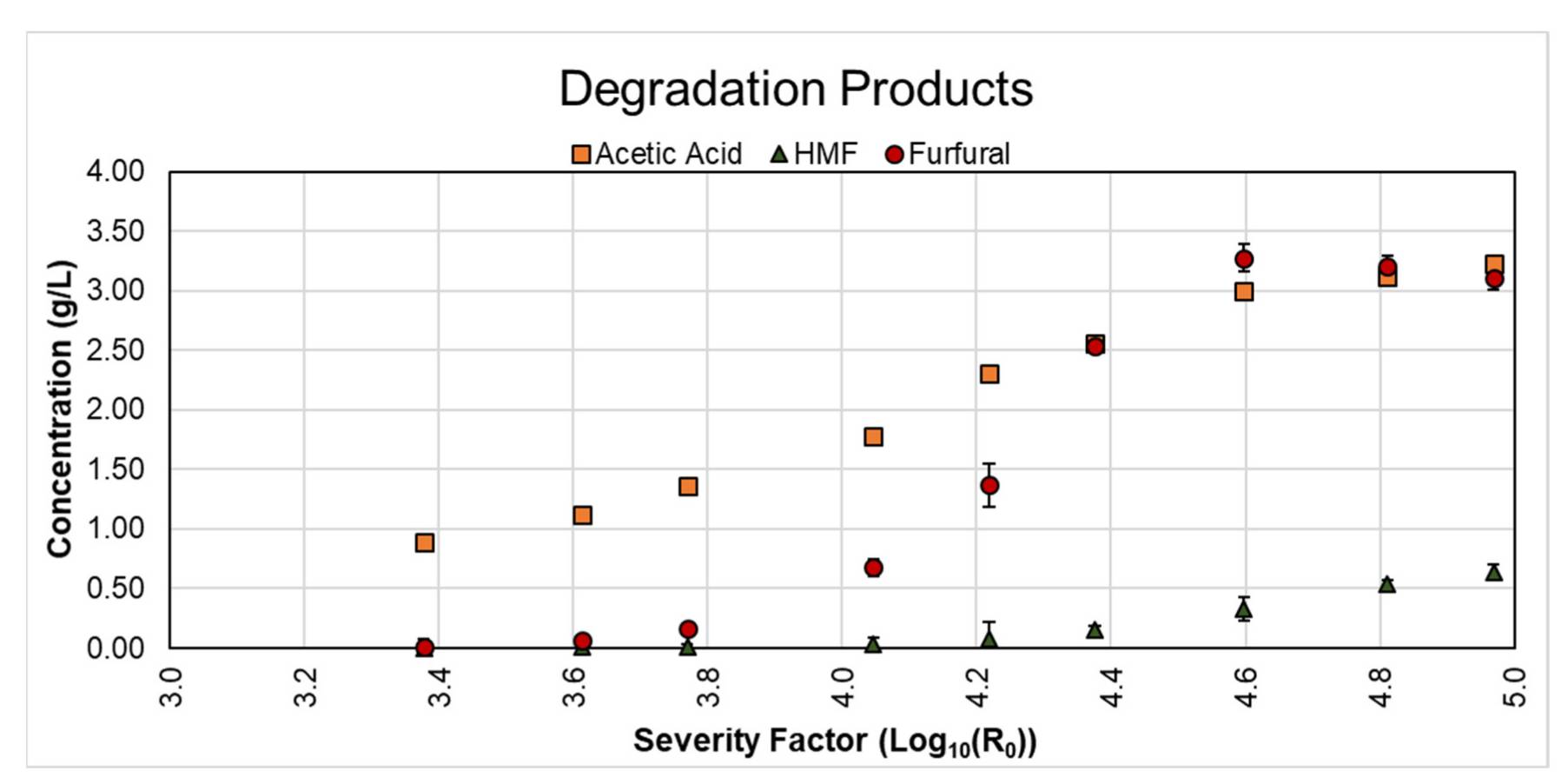

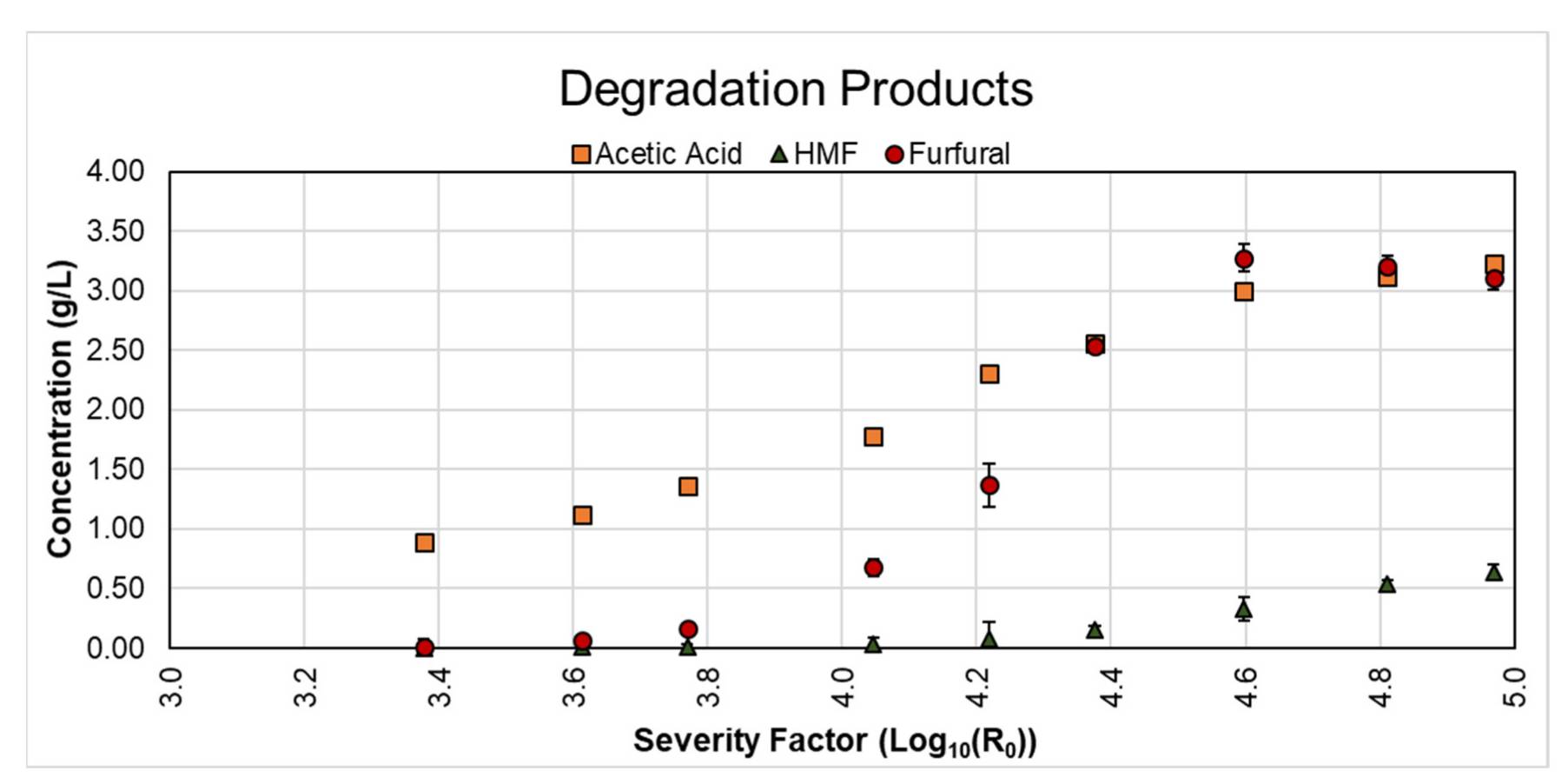

Published data

Effective fractionation of its different components during biomass treatment is essential for the overall value addition of biomass. In this study, wheat straw was used as raw material to obtain the optimum conditions for effective fractionation of components by analyzing lignin, total sugars, and degradation products in biomass treatment liquids. In this study, researchers used Liquid-hot-water (LHW) to hydrolyze wheat straw and optimized conditions to retain as much lignin as possible in the solid sample. Ultimately, it was found that the optimized conditions retained as much lignin as possible in the wheat straw for subsequent processing, and the sugars obtained from the LHW treatment could be used as a fermentation substrate. This study provided a demonstration for us to detect and analyze biomass process liquid.

Fig.1 Comparison of degradation product concentrations obtained under various treatment conditions.1, 2

Fig.1 Comparison of degradation product concentrations obtained under various treatment conditions.1, 2

FAQs

Q1: For what research purposes is biomass process liquid analysis typically used?

A1: Biomass process liquid analysis is essential to understand the efficiency and compositional changes of biomass conversion processes. Analysis of key parameters helps to improve the process conditions, which in turn improves the overall process efficiency and makes more efficient use of biomass resources such as lignocellulose.

Q2: What parameters are typically included in biomass process liquid analysis?

A2: Parameters analyzed in biomass process liquid include pH, saccharides, degradation products, degree of acetylation, etc. The composition and physical characteristics of biomass process liquid vary under different processing conditions. We develop tailor-made solutions to analyze biomass process liquid according to the client's specific requirements and application needs.

Customer Review

Custom Analytical Solutions

"We were very impressed with the level of service provided by Creative Biolabs. They were very professional and developed an apt analytical protocol according to our research needs. The entire analysis covered all the parameters we needed to measure, with detailed reports and clear explanations of the results. This biomass process liquid analysis service has helped us a lot in optimizing our biomass process."

Preferred Partner for Biomass Analysis

"Creative Biolabs is our preferred partner for analyzing biomass components and processing liquid. Their expertise and high quality of service were unparalleled. Working closely with us throughout the entire process, from protocol development to analysis of results, ensured that our research needs were met with precision and care, which allowed us to move forward smoothly with our biomass research projects."

References

-

Serna-Loaiza, Sebastian, et al. "Integral analysis of liquid-hot-water pretreatment of wheat straw: evaluation of the production of sugars, degradation products, and lignin." Sustainability 14.1 (2021): 362.

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Comparison of degradation product concentrations obtained under various treatment conditions.1, 2

Fig.1 Comparison of degradation product concentrations obtained under various treatment conditions.1, 2