Enzymatic Decomposition Reaction-based Residue Content Analysis Service

Comprehensive Residue Content Analysis Service at Creative Biolabs

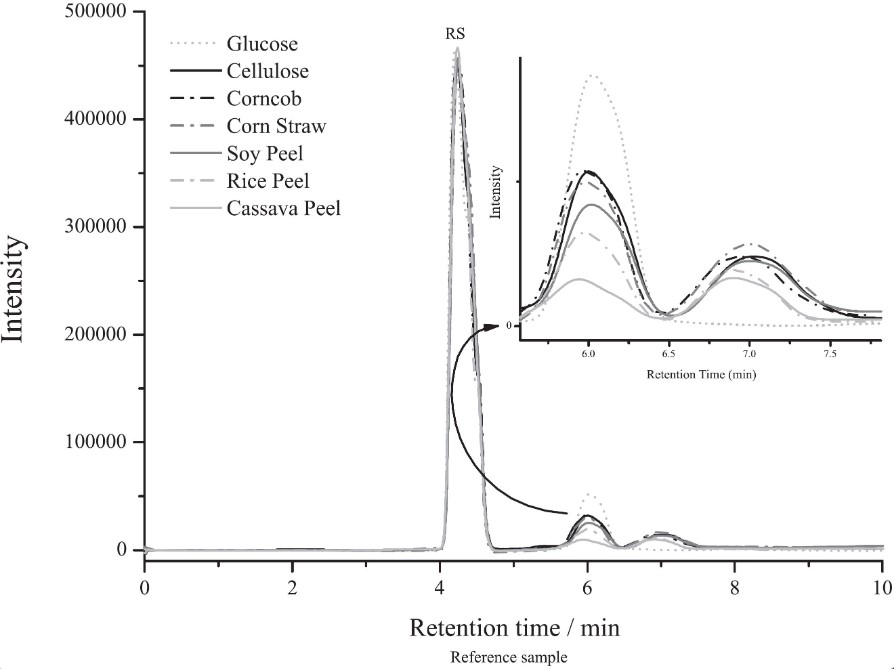

After biomass undergoes an enzymatic hydrolysis reaction, many residue components will be produced. These ingredients consist of the solid portion that remains after enzyme treatment. These residues usually contain polysaccharides such as cellulose, hemicellulose, lignin, and other organic substances that have not been enzymatically hydrolyzed. Analyzing the composition of these residues is of great significance for evaluating enzymatic reaction efficiency, optimizing process conditions, determining available components, predicting product types, and studying biotransformation mechanisms. Creative Biolabs has professional research teams and efficient analysis technologies. We provide a variety of biomass enzymatic hydrolysis reactions-based analysis services, including Enzyme Degradation Efficiency Analysis, residue component analysis, Inhibitor Analysis in enzymatic hydrolysis solution, Enzyme-Mediated Saccharification Efficiency Analysis, and Enzyme Activity Assessment services. For residue analysis after enzymatic hydrolysis, we have developed a comprehensive analysis process, the main steps of which include:

Sample preparation

We collect residue samples after enzymatic hydrolysis treatment and pre-process the samples as needed, such as grinding or drying, to ensure the uniformity and stability of the samples.

Residue content analysis

-

Cellulose, hemicellulose, and lignin analysis

We first extract cellulose, hemicellulose, and lignin using acidic, alkaline, or neutral solvents. We then use the Klason method or other chemical methods to determine the cellulose and hemicellulose content in the sample and use a diode array spectrophotometer to determine the lignin content in the samples.

-

Monosaccharide and polysaccharide analysis

We degrade polysaccharides into monosaccharide units through acid hydrolysis and then use chromatographic techniques such as high-performance liquid chromatography (HPLC) to separate and detect the content of various monosaccharides. Such as glucose, galactose, mannose, xylose, rhamnose, and arabinose.

-

Organic matter analysis

In addition, we use chromatography-mass spectrometry technology to identify and quantify organic compounds in the residue, such as fatty acids, volatile organic acids, etc.

Data analysis

We integrate and statistically analyze the analysis results of the above various components to obtain the overall composition and content of the residue. And provide clients with detailed reports according to the analysis results, including an overall description of the residue composition, the content of the main components, structural information, and possible application value.

Creative Biolabs has experienced scientists who can accurately analyze and interpret sample data and provide professional advice. We have established a complete quality management system to ensure the accuracy, reliability, and repeatability of the analysis process, and are committed to providing clients with high-quality enzymatic residue analysis results. If you need residue composition analysis services, please contact us and we will provide you with high-quality analysis services.

Published data

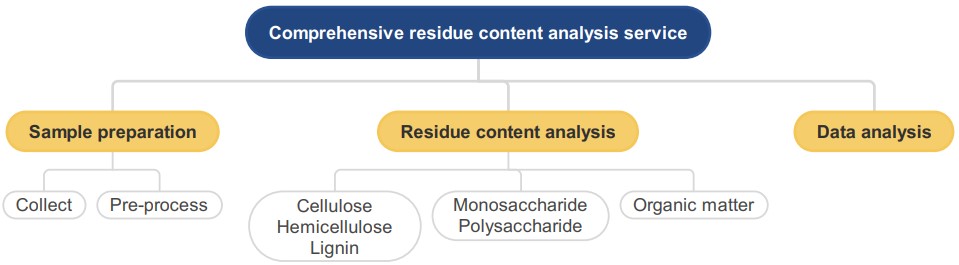

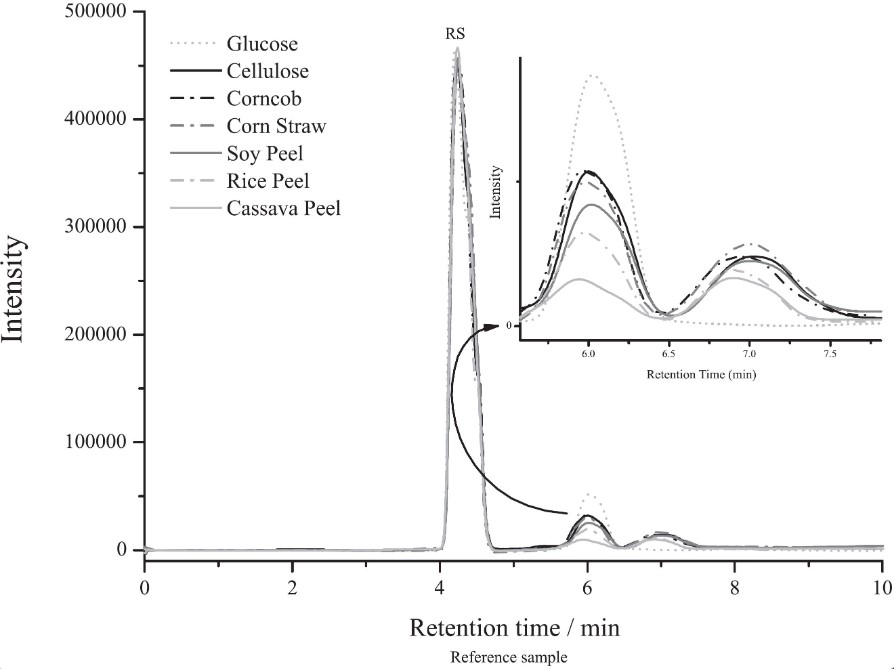

Organic wastes from agro-silvopastoral systems are used as raw materials for sustainable biofuels, especially the use of organic residues in lignocellulose to produce cellulosic ethanol and fermentable sugars. Lignocellulosic biomass includes hemicellulose, cellulose, and various hexose and pentose sugars. Converting residual cellulose in waste into high-value-added products such as biofuels has important application significance. The authors studied four major crop wastes (corn, rice, cassava, and soybean) and their residual components after enzymatic hydrolysis. First, the biomass sample was ground and extracted, then an enzymatic hydrolysis reaction was performed, the reaction solution was filtered, and the content of insoluble lignin in the filter residue was determined using gravimetric analysis; the soluble lignin was analyzed using UV-visible spectrophotometry at a wavelength of 280 nm. HPLC is used to analyze cellulose, hemicellulose, and the monosaccharides and disaccharides produced by decomposition. HPLC results showed the presence of cellobiose and glucose in the hydrolyzate. In addition, it was found in corn and soybean residues that the total reducing sugars in the two were compared with pure cellulose, reaching more than 50%, which showed that these crops could produce fermentable sugars through enzymatic reactions.

Fig.1 HPLC analysis of hydrolyzate.1, 2

Fig.1 HPLC analysis of hydrolyzate.1, 2

FAQs

Q1: What analytical methods do you usually use to determine the composition of the residue after enzymatic hydrolysis? What are the advantages of these methods?

A1: We mainly use the Klason method, HPLC, gas chromatography-mass spectrometry (GC-MS), and other methods to analyze residue components. These methods are highly accurate and sensitive, enabling efficient detection and quantification of target components.

Q2: How did you quantitatively analyze the contents of various compounds in the residue after enzymatic hydrolysis? What standards are used?

A2: We quantitatively analyze the compounds in the sample by establishing a standard curve or internal standard method, usually using international standard materials as reference standards.

Q3: How did you prepare the sample before analyzing the residue components? Do these processing steps affect the results?

A3: We routinely perform sample extraction, concentration, washing, and other pre-treatment steps to ensure the purity and stability of the sample, but at the same time try to avoid the loss or change of the compounds.

Customer Review

Professional Level

"Thanks to the professionalism and technical strength of the Creative Biolabs team, they demonstrated superb analytical capabilities in the analysis project of residue components after enzymatic hydrolysis and provided strong support for us to solve the problem."

Prompt Delivery

"Creative Biolabs's project delivery was very timely. Your team efficiently completed the analysis of the residue components after enzymatic hydrolysis and submitted the report within the scheduled time, allowing us to proceed to the next step of work on time. The entire cooperation process was very pleasant."

References

-

Cutrim, Fiama M., et al. "A study of chemical composition and enzymatic hydrolysis of solid organic waste from agrosilvopastoral systems." Journal of the Brazilian Chemical Society 30 (2019): 1955-1963.

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 HPLC analysis of hydrolyzate.1, 2

Fig.1 HPLC analysis of hydrolyzate.1, 2