Glycan Crystal Physical & Chemical Property Analysis Service

How Creative Biolabs' Glycan Crystal Physical & Chemical Property Analysis Service Can Assist Your Project

Glycans are pivotal molecules in both natural and manufactured products, influencing not only fundamental characteristics like sweetness and texture but also critical properties such as stability and bioavailability. At Creative Biolabs, we specialize in advanced Glycan Crystal & Glycoprotein Crystal Analysis, offering a precision-driven solution to a complex challenge. Are you currently facing difficulties in ensuring product stability, controlling crystal morphology, or optimizing the performance of your glycan-based formulations? Our Glycan Crystal Analysis Service helps you gain deep insights into your materials, predict their behavior in final products, and streamline your development process through our advanced analytical platforms and expert scientific team. Understanding the solid-state behavior of glycans is crucial for ensuring the quality, stability, and efficacy of your products, from food ingredients to pharmaceutical excipients. Our service provides you with a comprehensive understanding of your glycan crystals, moving beyond simple composition to reveal their Morphology, Thermal behavior, and purity. These insights are essential for a wide range of applications, including optimizing the shelf-life of food products, improving the dissolution rate of drug formulations, and preventing undesirable physical changes like caking or agglomeration. We offer a data-driven approach to help you make informed decisions, mitigate risks, and accelerate your product development lifecycle.

How to Provide the Glycan Crystal Physical & Chemical Property Analysis Service

The physical and chemical properties of glycan crystals are a key determinant of their functionality in both food and pharmaceutical applications. The crystalline structure of glycans dictates their solubility, thermal stability, and mechanical strength. Literature has demonstrated that controlling crystal morphology and size is critical for final product quality, and that the solid-state behavior of a glycan has profound implications for its purification and stability. Our service is provided through a multi-faceted approach combining state-of-the-art instrumentation with expert data interpretation. Our process involves a sequence of specialized analyses designed to build a complete profile of your glycan material. We work closely with clients to understand their specific needs and tailor the analytical plan accordingly. This includes determining the correct sample preparation methods, selecting the most appropriate analytical platforms, and providing a final report that is not just a collection of data, but a strategic guide to product optimization.

Key Steps Involved

Sample Submission

Our experts work with you to define the project scope, objectives, and analytical requirements. You submit the glycan samples and supporting documentation to our facility.

Crystal Morphology and Size Analysis

We begin with a detailed analysis of your crystal samples using advanced microscopy techniques and particle size analyzers. This step provides a visual and quantitative report on crystal shape, size distribution, and the presence of any unwanted conglomerates. This is a critical first step to understand and control the final physical properties of the product.

Thermal and Crystallographic Characterization

Using Differential Scanning Calorimetry (DSC) and X-ray Diffraction (XRD), we determine key thermal parameters like glass transition temperature (Tg), melting point, and enthalpy of fusion, as well as the crystallographic structure. These insights help predict the material's stability and behavior under various processing and storage conditions.

Physicochemical and Purity Analysis

We perform a range of analyses to determine purity and other key physicochemical characteristics. This includes Karl Fischer (KF) titration and Dynamic Vapor Sorption (DVS) to measure moisture content and hygroscopicity, which are directly related to stability and shelf-life. Purity analysis is conducted using high-performance liquid chromatography (HPLC) and mass spectrometry (MS) to identify and quantify all components in the sample. This includes not only the target glycan but also any impurities, which can significantly affect crystallization and final product properties.

Data Integration and Reporting

All data from the various analytical platforms are compiled, cross-referenced, and synthesized by our scientific team into a comprehensive report. The report includes a detailed interpretation of the findings, a clear conclusion, and actionable recommendations to optimize your processes.

Why Is It Necessary to Provide This Service?

The necessity for a dedicated glycan crystal physical & chemical property analysis service is clear in today's market. Companies can no longer rely on trial and error to ensure product quality and stability. The physical form of a glycan, from its moisture content to its crystal shape, is directly linked to its performance. For example, in the food industry, a low glass transition temperature (Tg) can lead to caking and loss of product integrity, while in the pharmaceutical sector, crystal form can affect dissolution rate and bioavailability. Providing this service is necessary to:

Published Data

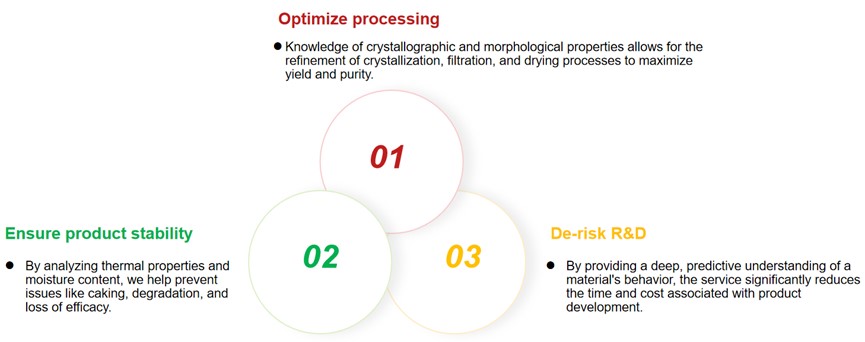

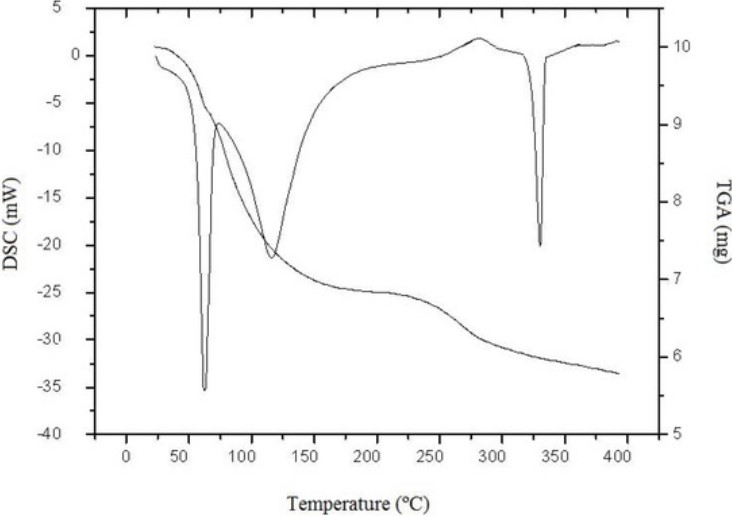

This research investigated the use of a low-cost substrate, yam bean, for the microbial production of chitin and chitosan by the fungus Mucor circinelloides. The study found that this method yielded significant amounts of biomass and biopolymers, with peak chitosan production occurring after 48 hours of cultivation and chitin production peaking at 72 hours. The thermal properties of the produced chitosan were meticulously analyzed using thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), as detailed in the following Figure of the study. The TGA curve revealed a three-stage degradation process. An initial weight loss was observed, which the researchers attributed to the evaporation of moisture from the sample. A more substantial decomposition phase commenced at approximately 170 °C, signifying the breakdown of the polymer's structure. The final stage, starting at 335 °C, corresponded to the complete consumption of the remaining carbonized residue. The DSC curve further elucidated these thermal events, displaying two distinct endothermic peaks. The first, a broad peak between 26 °C and 182 °C, was linked to the desorption of water molecules from the biopolymer. A second endothermic peak, observed at a higher temperature, was consistent with the polymer's thermal decomposition, confirming the observations from the TGA data. The analysis suggests that the thermal stability of the chitosan is inversely proportional to its degree of deacetylation. Overall, the study confirms that yam bean is an effective and economical substrate, producing a high-quality chitosan with properties that are well-suited for various uses.

Fig.1 Thermal analysis of microbial chitosan.1

Fig.1 Thermal analysis of microbial chitosan.1

FAQs

What is the typical turnaround time for a standard analysis?

Our standard analysis has an estimated turnaround of 4-8 weeks. This timeframe can be influenced by the sample's complexity, the number of analyses requested, and whether we need to develop a custom analytical method for a novel glycan. We are committed to keeping you informed throughout the process and will provide a more precise estimate during our initial consultation.

How do you ensure the accuracy of your moisture analysis, especially with highly hygroscopic samples?

We use state-of-the-art Dynamic Vapor Sorption (DVS) for a precise and repeatable measurement of a sample's hygroscopicity profile. This method goes beyond a simple Karl Fischer measurement to show how your material interacts with moisture over a range of humidity levels, providing a more robust picture of its long-term stability.

Can you help us optimize our crystallization process based on your analysis?

Absolutely. Our comprehensive reports don't just provide data; we provide actionable insights. By analyzing your crystal's size, shape, and stability in relation to your solvent system and process parameters, our team can offer data-backed recommendations to improve your crystallization process and achieve the desired final product attributes.

Customer Review

Comprehensive Particle Size Analysis

"Their particle size analysis was incredibly thorough. Using Creative Biolabs' service has facilitated a major breakthrough in controlling the texture of our products, allowing us to achieve the desired mouthfeel without any undesirable caking."- A. Ma***, Scientist.

Detailed Report

"The detailed report on moisture content and hygroscopicity gave us the confidence we needed. Using Creative Biolabs' analysis has greatly improved our ability to predict long-term product stability under different storage conditions."- G. Ke***, Manager.

How to Contact Us

Creative Biolabs is ready to partner with you to solve your most complex glycan-related challenges. Our experts are standing by to discuss your project, provide a detailed quote, and help you unlock the full potential of your materials. Please contact our team for more information and to discuss your project.

Reference

-

Fai, Ana Elizabeth C., et al. "Physico-chemical characteristics and functional properties of chitin and chitosan produced by Mucor circinelloides using yam bean as substrate." Molecules 16.8 (2011): 7143-7154. Distributed under an Open Access license CC BY 3.0, without modification. https://doi.org/10.3390/molecules16087143

For Research Use Only.

Related Services

Fig.1 Thermal analysis of microbial chitosan.1

Fig.1 Thermal analysis of microbial chitosan.1