Creative Biolabs offers comprehensive glycosylated polymer engineering services, delivering tailor-made glycopolymers with precise carbohydrate modifications to meet the evolving demands of drug delivery, regenerative medicine, immunomodulation, and biosensor design. Our platform supports controlled glycopolymer synthesis, analytical characterization, and biological testing, covering polymers such as PEG, PLGA, polysaccharides, and peptide-based macromolecules. Backed by years of experience in polymer glycoengineering, we help researchers build biocompatible and bioactive materials enriched with functional glycans—such as mannose, fucose, and sialic acid—to improve molecular targeting, minimize immunogenicity, and enhance therapeutic performance.

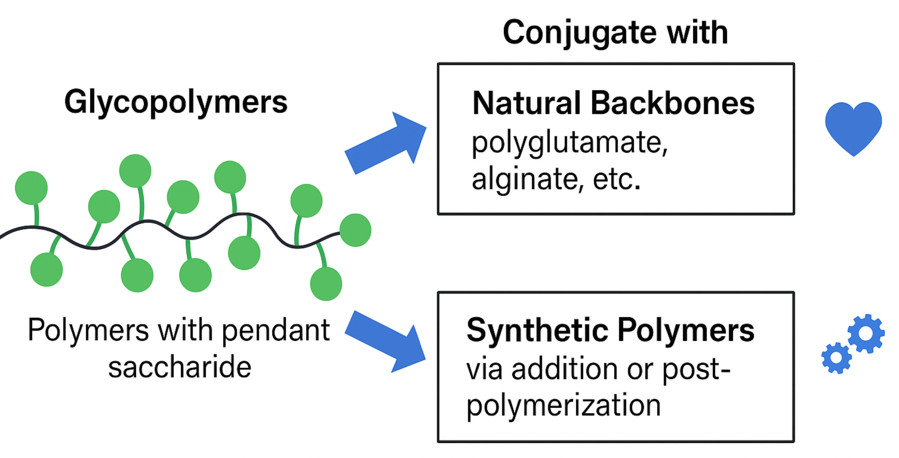

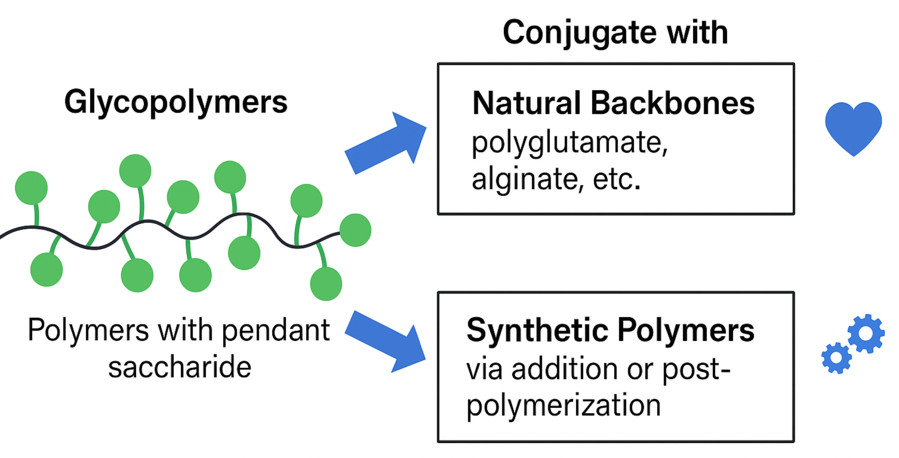

Fig.1 Glycopolymers are linked to natural or synthetic polymers.

Fig.1 Glycopolymers are linked to natural or synthetic polymers.

Glycosylation Matters: Why Use Glycosylated Polymers?

Glycans do not just serve as passive decorations. They define molecular identity, recognition, and fate in biological systems. Our polymer glycosylation platform allows precise tuning of these interactions. Creative Biolabs designs modular glycopolymer platforms with customizable glycan displays, precisely engineered to support:

-

Targeted drug delivery

-

Cell–matrix interactions in regenerative medicine

-

Glycan-recognition biosensors

-

Low-fouling medical device coatings

Our Workflow: From Concept to Glycosylated Product

1. Initial Consultation

We begin with a technical consultation to define:

-

Target polymer and functional groups

-

Desired glycan pattern (e.g., high-mannose, sialylation)

-

Intended application and performance criteria

Within this stage, you receive:

-

Feasibility assessment

-

Technical roadmap

-

Customized quotation and timeline

2. Target Material Sourcing

Choose from two modes depending on your R&D setup:

Option 1: Client-Supplied Material

You send us the target material (peptides, PLGA, PEG, etc.), especially if:

-

You want to reduce project cost

-

You already optimized the polymer scaffold

-

Proprietary materials are involved

Option 2: Full-Service Synthesis by Creative Biolabs

We handle everything—from polymer backbone synthesis to pre-glycosylation purification. We work with:

-

Synthetic polymers (e.g., PEG, PLGA, polyacrylates)

-

Natural polymers (e.g., chitosan, dextran)

-

Peptides and small proteins

3. Precision Glycosylation of Target Polymer

Using either chemical conjugation, chemoenzymatic ligation, or click chemistry, we append the selected glycan moieties:

-

Covalent attachment to amine, hydroxyl, or carboxyl groups

-

Glycan selection includes GlcNAc, GalNAc, mannose, sialic acid, fucose, lactose, and more

We ensure:

-

Regioselective glycan placement

-

High glycan density without compromising polymer architecture

-

Scalable modification strategies for both research and clinical batches

4. Purification, Validation & Delivery

Each glycosylated product undergoes comprehensive and strict analysis for desired purification and validation outcomes. Purified glycopolymers are delivered in freeze-dried or solution form and are ready for downstream application.

Sample Submission & Project Start

To initiate your glycopolymer project, please prepare:

-

Target polymer (if available)

-

Desired glycan(s) and density

-

Project timeline and deliverables

Polymer Types and Use Cases

Glycosylated PEG (Polyethylene Glycol)

PEGylated glycopolymers are key to:

-

Stealth nanoparticles with mannose for macrophage targeting

-

Sialylated PEG hydrogels for anti-inflammatory coatings

-

Fucosylated PEGylated surfaces for immune regulation studies

Glycosylated PLGA (Poly (lactic-co-glycolic acid))

PLGA backbones modified with terminal glycans support:

-

Oral drug delivery via mucus penetration and M-cell targeting

-

Controlled-release microparticles for cancer vaccines

-

Immune-adjuvant carriers using high-mannose density

Polysaccharide-Based Glycopolymers

Natural polysaccharides offer:

-

Biodegradable glycosylated scaffolds

-

Gene delivery vectors via glycan-receptor targeting

-

Hydrogel matrices for stem cell culture

Application Pipeline: Helping You Solve Real Challenges with Glycosylated Polymers

At Creative Biolabs, our glycosylated polymer engineering services are designed to bridge the gap between polymer material design and biological function. By precisely introducing glycans onto synthetic or natural polymers, we help you transform inert materials into targeted, bioresponsive platforms tailored for your application.

-

For targeted drug delivery, we help overcome poor tissue selectivity by engineering glycopolymer-coated nanoparticles that home in on disease-associated lectins—such as those overexpressed in tumors or inflamed tissues.

-

In regenerative medicine, we design mannosylated scaffolds that go beyond structural support. These scaffolds actively guide immune cells—especially macrophages—toward a healing phenotype, setting the stage for tissue regeneration, not just repair.

-

If you're working on mucosal vaccines or immunotherapies, our multivalent glycan displays mimic natural pathogen glycans, enhancing immune cell recognition and boosting mucosal immune activation—where traditional adjuvants often fall short.

-

When it comes to diagnostics, false signals from nonspecific binding can derail an otherwise brilliant assay. Our sialylated polymer coatings significantly reduce background noise on biosensor surfaces, helping you see what truly matters.

-

And for implantable devices, fucosylated polymers help form anti-adhesive surfaces that resist bacterial colonization—offering a chemical-free strategy to reduce infection risk and extend device lifespan.

Why Choose Creative Biolabs?

-

From design to delivery, backed by expert polymer chemists and glycobiologists

-

Accommodates synthetic polymers, peptides, oligonucleotides, and hybrid scaffolds

-

Optimized protocols for various glycan–polymer combinations

-

On-site HPLC, MS, NMR, and bioassay capabilities for thorough characterization

Related Services You May Need

To complement glycosylated polymer engineering, we provide additional platforms for glycoengineering across biomolecule classes:

-

Custom Glycosylation of Expressed Proteins/Peptides

Tailored glycosylation of recombinant peptides and proteins to modulate structure, function, and pharmacokinetics.

-

Glycosylated Antibody Engineering Service

Fc glycan modification to improve ADCC, CDC, serum half-life, and therapeutic efficacy.

-

Glycolipid Engineering Service

Synthesis of glycosylated lipids for vaccine development, membrane targeting, and glycolipid-based adjuvants.

-

Glycosylated Oligonucleotide Engineering Service

Enhance nucleic acid drugs with glycans to improve stability, reduce immunogenicity, and control delivery.

-

Custom Glycosylation of Small Molecule Drugs

Sugar-conjugated small molecules for improved solubility, targeted delivery, and controlled pharmacokinetics.

For quotation requests, feasibility assessments, or technical consultation on glycosylated polymer services, our scientific team is here to help. Let's customize the next generation of glycosylated macromolecules—engineered for performance, guided by glycobiology. Contact us today!

Reference

-

Fang, Yan, et al. "Polymer membrane with glycosylated surface by a chemo-enzymatic strategy for protein affinity adsorption." Catalysts 10.4 (2020): 415. https://doi.org/10.3390/catal10040415

Resources

For Research Use Only.

Contact Us

Follow us on

Contact Us

Follow us on

Fig.1 Glycopolymers are linked to natural or synthetic polymers.

Fig.1 Glycopolymers are linked to natural or synthetic polymers.